Steam Curing Cinder Blocks

Accurate steam control for precision autoclave dryer performance

Precise control of steam temperature and pressure while steam curing cinder blocks is critical to the quality of the finished product.

Building bricks of varying types are all around us in cityscapes and neighborhoods and they have been used in different types of construction for centuries. Originally, bricks were molded by hand, fired, or dried out in the sun before use, but today bricks are mass-produced in molds, extruded and cut.

Cinder blocks, or breeze blocks as they are sometimes known, are a newer choice of construction material originally made with coal cinders (hence the name) and bonded together with cement. Today these blocks are made with added materials such as sand, lime, fuel ash, or pumice. Aeration techniques are also common, making these blocks lighter than ever. Cinder blocks are cheaper and more versatile than bricks and are used in foundation walls and partition walls for their lightness, strength, insulating and sound-reducing properties.

Preparation techniques have changed over the years but curing cinder blocks properly is still extremely important to ensure they have the correct internal structure and mechanical properties needed for construction. Curing generally takes place in large ovens or autoclaves where the precise control of steam temperature and pressure is critical to the quality of the finished product and not all steam control valves are up to the challenge.

Jordan Sliding Gate Valves Control Challenging Autoclave Dryer Temperature

Jordan Valve sliding gate technology is ideally suited for use in industrial steam applications and is a perfect fit for the accuracy and precise control needed for autoclave steam control.

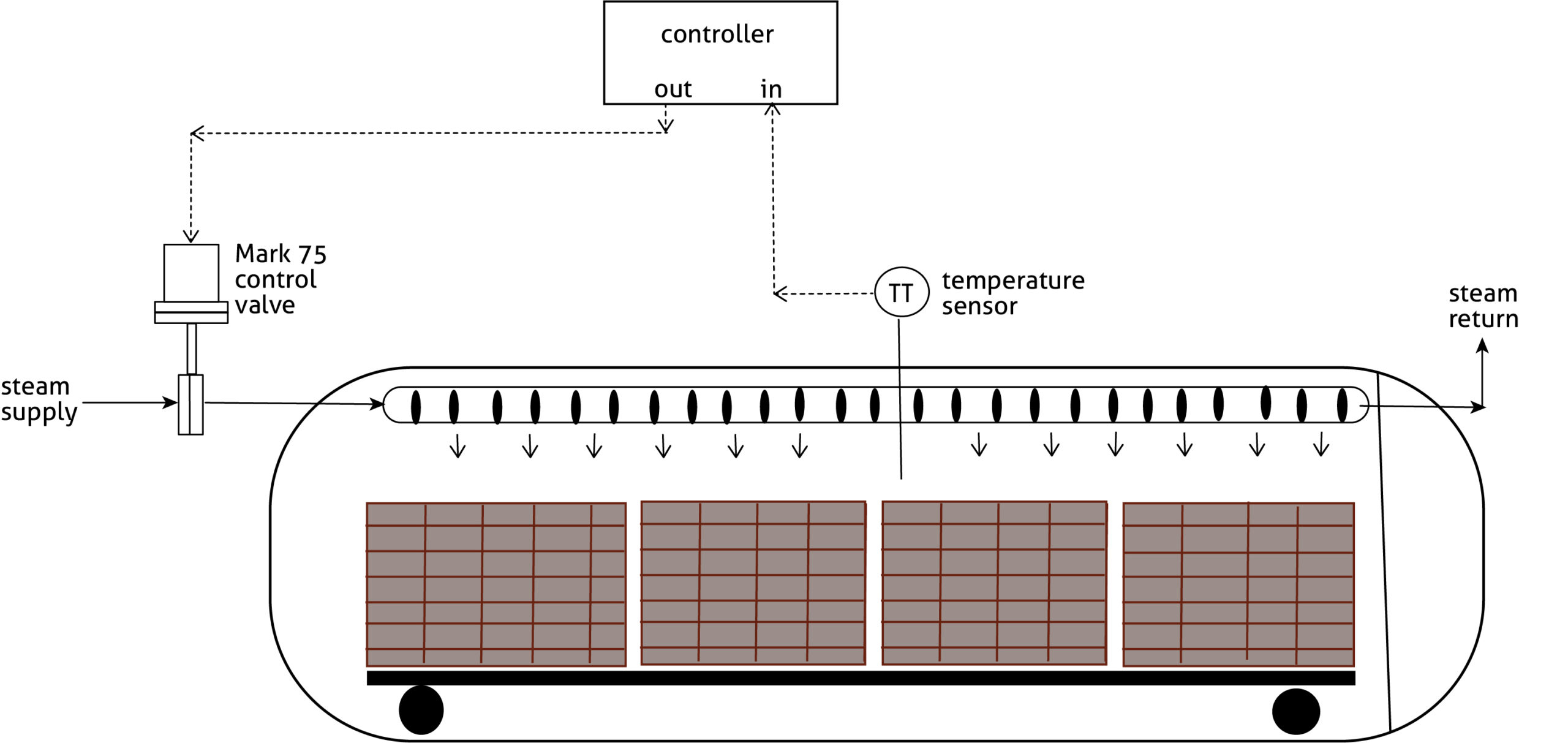

After the cinder blocks are wet-formed, they are loaded onto a kiln car and rolled into a large kiln or autoclave for steam curing. The autoclave temperature is slowly raised at a carefully controlled rate to allow the moisture to be removed from the blocks without introducing structural defects that can result in cracking or crumbling. If the blocks are dried too quickly there is even a risk that they may explode. Consequently, accurate and precise steam control is absolutely critical to the overall quality of the finished product.

The critical part of the process is supplying steam to the autoclave to dry or ‘cook’ the cinder blocks at the exact ramp-up rate, holding temperature, and ramping down rate so that the internal moisture evaporates, and the blocks are conditioned into a uniformly strong final product while preserving their integrity. Furthermore, depending on the intended use of the final product, different ‘recipes’ are used to provide differing physical properties of the blocks. This ‘recipe’ information can be uploaded to the autoclave controller with specially developed combinations of temperature, pressure, up and down ramp rates and overall curing time. The Jordan Valve Mark 75 sliding gate valve is capable of offering an extremely high degree of accuracy, precision and repeatability for the control steam, pressure and temperature essential to the quality of the finished cinder blocks.

The Mark 75 wafer style control valve was developed as the next generation of control valve featuring all the benefits of the time-tested sliding gate design in a lightweight, compact, wafer-style body. Using sliding gate technology, Mark 75 valves are more compact than traditional globe valves, easier to maintain, more accurate, more repeatable and require less energy to operate. Using the Jordan Sliding Gate Valve will increase your level of control while decreasing the overall operating costs of your system ensuring a consistently high-quality finished product.

Let us help you find the right valve for your application.

Related Resources

Steam Sterilization

Jordan Valve sliding gate valves with Jorlon® diaphragms outlast in challenging steam sterilizing process

Precision Steam Control

Jordan Sliding Gate Valve for Precise, Efficient Steam Control

Steam Valve for Tire Curing Press

Jordan Valve sliding gate technology outperforms in challenging tire curing process

Better Steam Pressure Control Improves Drying for Coating Process

Jordan Mark 701 Sliding Gate Control Valves give Tighter Temperature Control, Faster Throughput

Boiler Feedwater Control

Jordan Mark 33 feedwater control valve maintains accurate level in boiler steam drum.

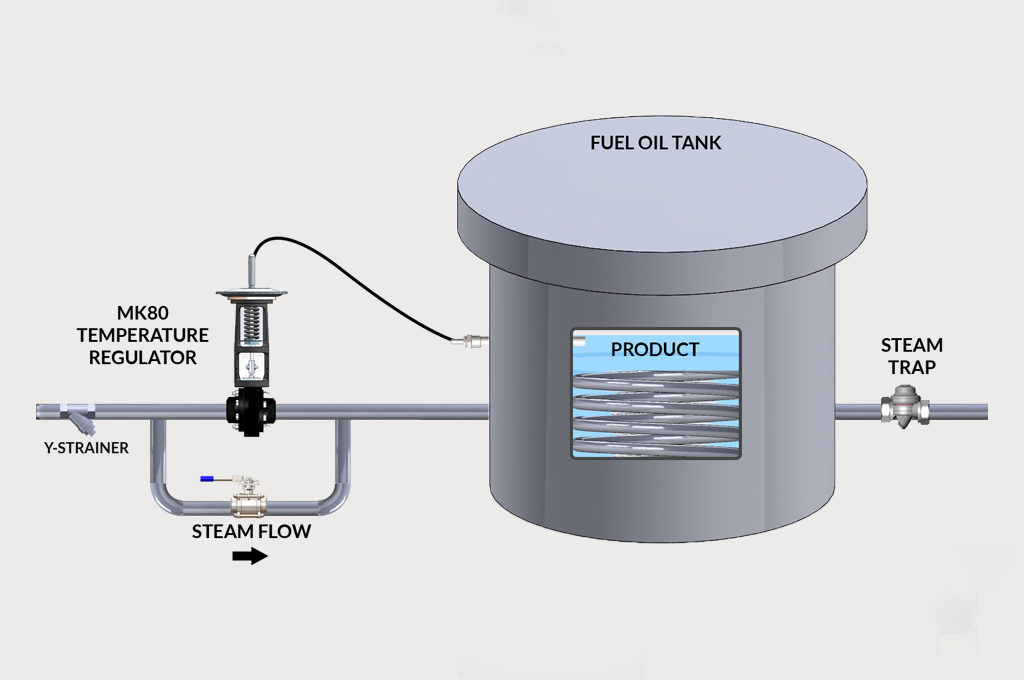

Steam Temperature Control of Jacketed Tanks

Steam pressure control is vital for maintaining consistent tank jacket temperature

How Temperature Regulators and Control Valves Work

Using Self-Operated Temperature Regulators to Control Steam

Mark 75 Series Wafer Style Control Valves

Mark 75 Series Wafer Style Control Valves