Sliding Gate Valves

You will notice something different in many Jordan valves … the sliding gate seat. A remarkably simple concept that offers superior performance and benefits not found in traditional rising stem and rotary valves.

What is the Jordan Valve Sliding Gate Seat & how does it work?

The sliding gate seat is made up of two primary parts:

- A movable disc

- A stationary plate with multiple orifices

Together, this seat set achieves levels of performance, reliability and accuracy that are hard to find in other designs.

Advantages Of The Sliding Gate Seat Set

There are many different benefits of Jordan Valve’s Sliding Gate technology including:

Short Stroke, Fast Response

The most important thing that differentiates our technology from competitors is the shorter stroke life which makes the diaphragm life a lot longer. Almost all pressure regulators are spring loaded. As the regulator pressure goes down, it has to work harder to press down on the diaphragm which causes the diaphragm to stretch out. This means the springs have to work even harder and eventually the diaphragm wears out.

The total stroke length is just a fraction of the equivalent globe valve. In pressure regulators, the stroke length is typically ⅓ that of a globe valve, reducing the amount of droop (deviation from setpoint) in the regulator.

In control valves, the sliding gate allows the use of reduced air consumption and weight minimization. The short stroke reduces packing wear and lengthens the diaphragm life.

Quiet Operation

Compared to conventional globe and cage designs, the sliding gate seat generates between 5-10dB less noise. OSHA publishes regulations for noise levels and determines what PPE is required for people exposed to noise. You won’t find a premium price added for “low-noise trim”. The sliding gate valve is inherently quieter than other types of valves because:

- The disc and plate remain in constant contact, eliminating the chatter found in globe-style designs

- The straight-through flow passage minimizes turbulence found in globe and rotary designs, a primary cause of valve noise

- The multiple orifices in the plate and disc divide the flow into smaller flow streams, resulting in less noise

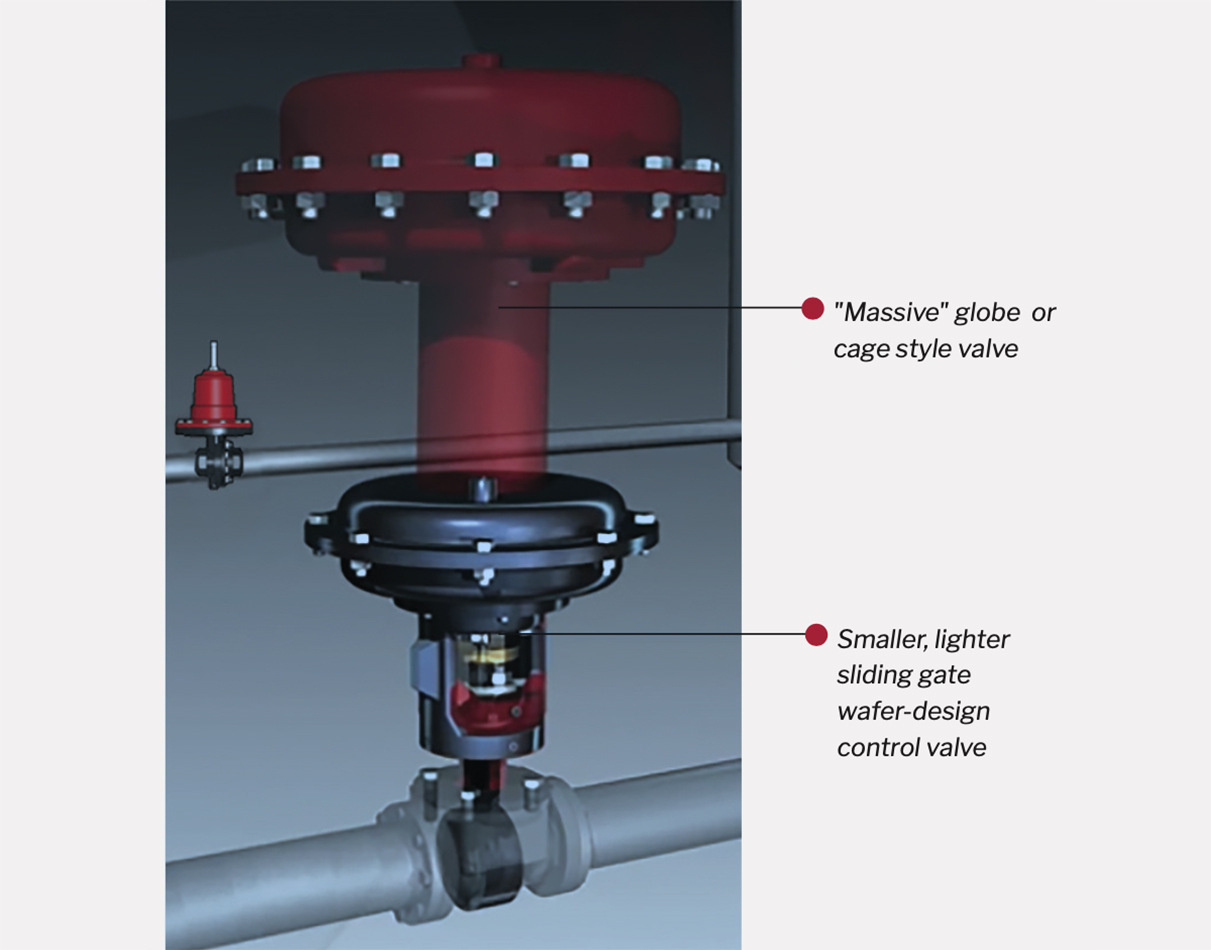

Smaller & Lighter Weight

As the line size increases, so too does the size and weight of the valve. Due to the short stroke length, a sliding gate valve is typically smaller and lighter weight than a globe/cage style valve.

For example, with the Mark 75 Series control valve, the shipping size, weight, packing waste and costs decrease dramatically due to the wafer style design!

We also have more CV ranges. In the 2” Mark 60 regulator, our CV range is up to 30. Our competitor is 12.5 cv. This means you don’t have to go up to a 2-1/2” size to get the CV you need — which means a lighter weight and less expensive valve.

Reduced Turbulence

The tortuous flow path of a globe style design creates greater turbulence, noise and wear – reducing seat life and compromising control performance. When used in applications where flashing or cavitation occurs, damage to the valve body is common – and is mitigated only through expensive material upgrades or elaborate trim configurations.

A rotary control valve has similar wear issues due to turbulence. When throttling, the control member of a rotary control valve will direct the flow to the sealing area of the seat, causing premature seat leakage.

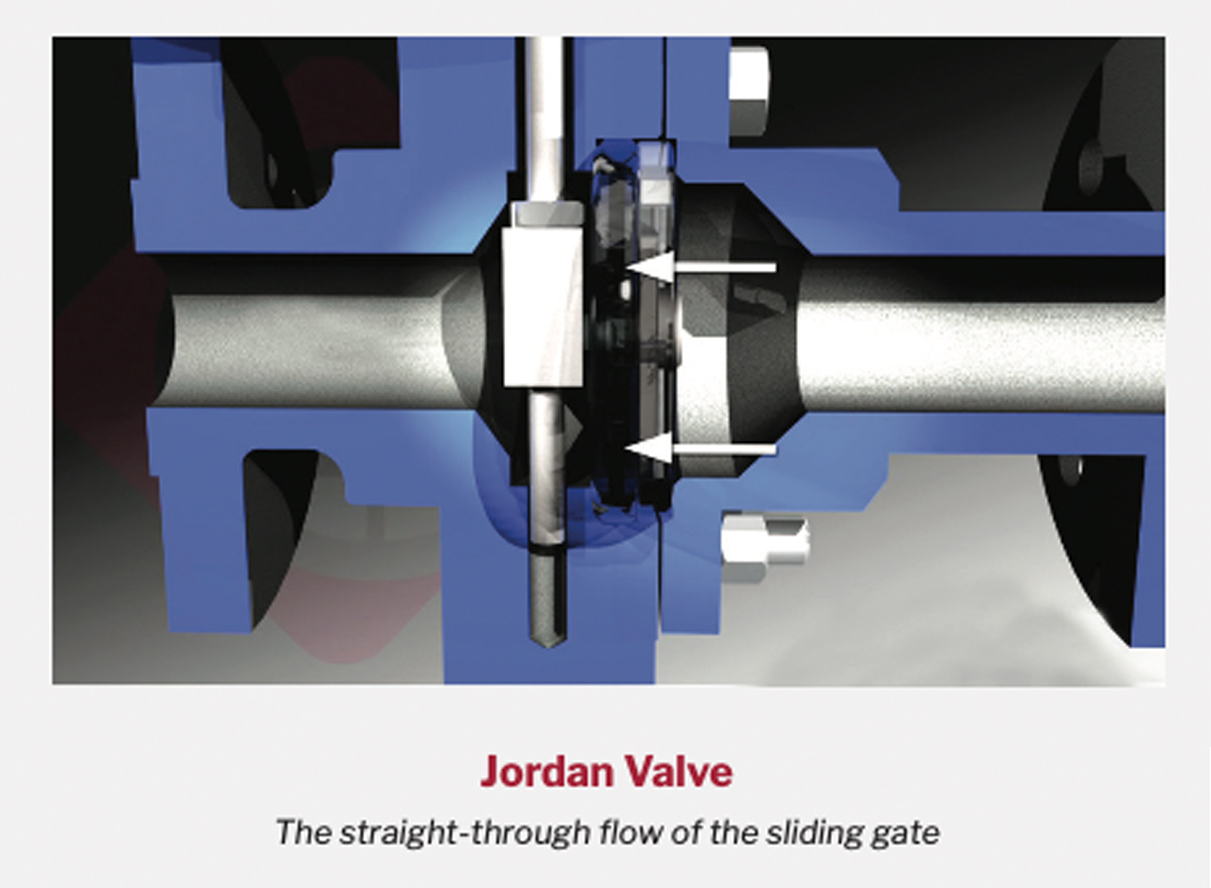

In contrast, the multi-orifice straight through flow path of the sliding gate valve reduces turbulence and leads to quieter operation, reduced wear, longer seat life and better control.

For example, when combined with the ultra-compact wafer body design of the Mark 75 Series, erosion of the seats and valve body is virtually eliminated – resulting in dramatic cost savings.

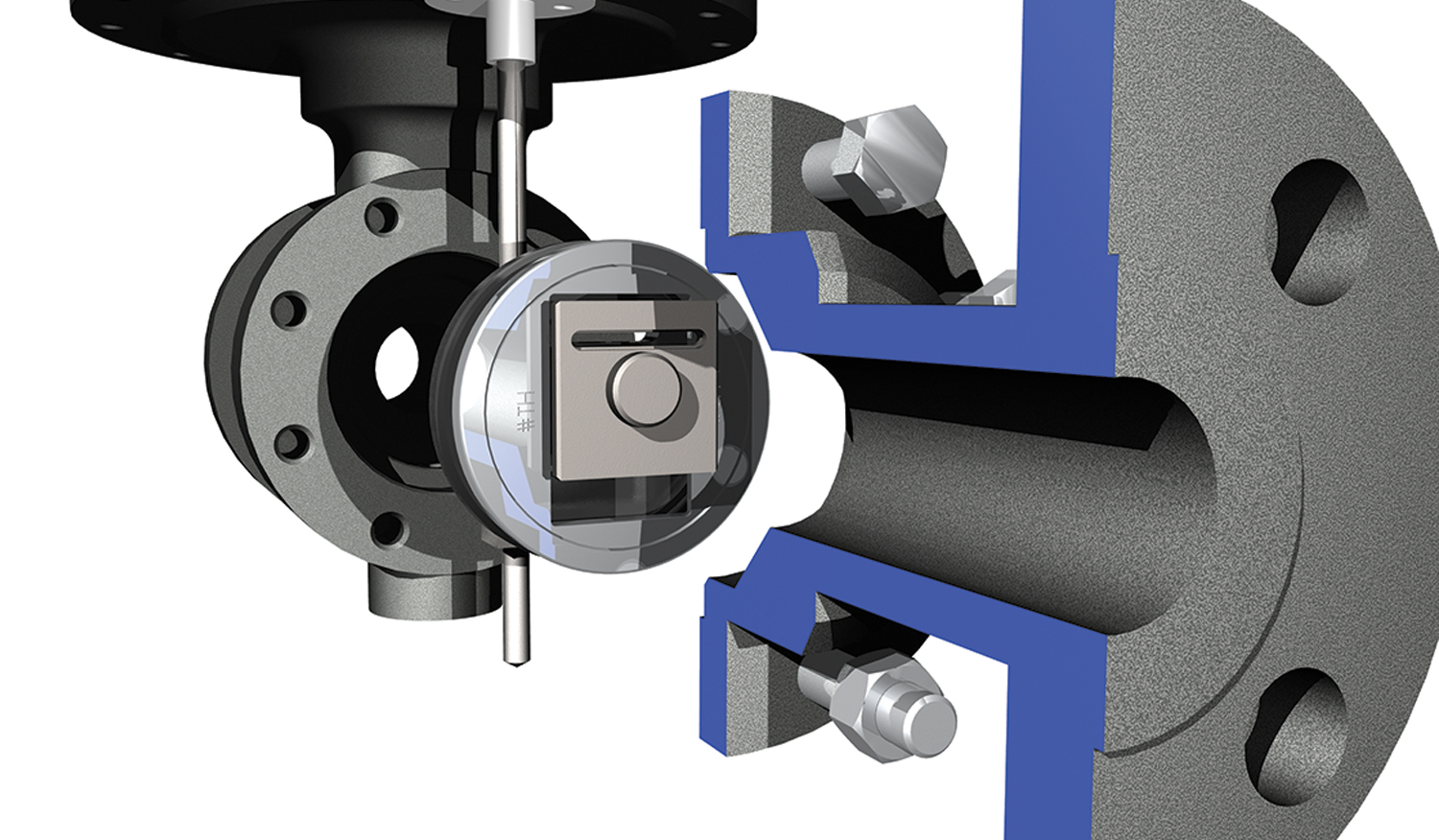

Straight-Through Flow

The Sliding Gate seat set is perpendicular to the flow, unlike the traditional globe style design. With straight through flow, the turbulence is reduced and superior trim life is achieved.

The sliding gate design provides exceptional flow control since the flow works with the seat and not against it. In a typical globe style design, the flow goes underneath the plug, working against the plug. With the sliding gate, the flow pushes the disc against the plate, helping to hold the desired setpoint. This also enables the disc and plate to lap and clean themselves as the valve modulates. The sliding gate design “wears in” instead of wearing out.

Seat Coatings

Jordan Valve offers coatings and seat materials to meet almost any application need. Jorcote, our standard seat material, is a proprietary composite coating on Stainless Steel. This material is extremely hard and delivers outstanding performance.

Other coatings include Teflon and chrome plating.

Tight Shutoff

The sliding gate design provides an area of closure, not a line of closure. When the valve is closed, the disc and plate are overlapped by 1/32″. This area of closure helps reduce the effects of wire draw which is one of the most common causes of seat leakage.

What does this mean for you? Less maintenance and downtime with more opportunity to increase yields and profits.

Types Of Jordan Valves & Regulators Using Sliding Gate Technology

Our sliding gate technology is used on both our:

- Jordan Valve: Sliding Gate Control Valves

- Jordan Valve: Sliding Gate Pressure Regulators

- Jordan Valve: Sliding Gate Back Pressure Regulators

Jordan Valve: Sliding Gate Control Valves

Our sliding gate control valves are small, lightweight solutions that provide exceptional flow control and reduced turbulence. We carry the following control valves with sliding gate technology:

Note: Each series may have additional models or options which substantially expand the series’ capabilities. Reduced Cv’s can be used in any size valve as long as it is smaller than the standard size for the valve.

Jordan Valve: Sliding Gate Pressure Regulators

We carry the following regulators with our sliding gate technology:

Note: Each series may have additional models or options which substantially expand the series’ capabilities. Reduced Cv’s can be used in any size valve as long as it is smaller than the standard size for the valve.

Jordan Valve: Sliding Gate Back Pressure Regulators

We carry the following regulators with our sliding gate technology:

Ready to leverage our powerful sliding gate technology on your net project? Shop our products today.

Sliding Gate Maintenance & Durability

The simple design of the sliding gate valve makes maintenance easy to perform. Disassembly of the valve is very simple, and since the seats are not pressed or screwed into the valve body, they conveniently lift out.

Should your flow requirements change, interchangeable Cv’s (Kv’s) are available in coefficients as low as 0.0008 (0,0007) and as high as 600 (519) (depending on body size).

Durability Details

- Self-Cleaning: the movement of the sliding gate seats generates a self-cleaning action, with any leak-producing deposits being cleaned off by the sharp shearing action of the disc moving across the plate.

- Materials: our proprietary Jorcote seat material is extremely hard (@RC85) and delivers outstanding wear resistance.

- Multi-orifice: The multi-orifice design separates erosive flow into smaller, less damaging streams. The erosive forces are dissipated over the numerous slots eliminating the single wear points associated with other valve types and quieter operation.

- Eliminates Damaging Chatter: The upstream pressure holds the disc in constant contact with the plate. This prevents the sudden, damaging (and noisy) contact which occurs in some globe designs. The constant contact between the disc and plate actually generates a self-lapping effect which results in less friction and tighter shut off than when the valve leaves the factory.

- Engineer tested: Jordan Valve engineers conducted a steam test using 250 psig (17,2 barg) saturated steam. The test was designed so that the valve would fully stroke open and closed each time it was actuated. The pressure drop across the valve was the full 250 psig (17,23 barg). The results were impressive. Our standard Jorcote/Chrome seat combination had less friction after 70,000 cycles than when it was new and the seat leakage was well below ANSI Class IV limits. Jordan Valve engineers are constantly testing and improving our products to ensure optimal high performance in the field.

Industry Applications

Our sliding gate control valves and regulators are built for the following industry applications:

- Utility

- Petroleum

- Refining

- Chemical

- Tank heating

- Steam tracing

- Heat exchangers

- Air drying

- Regulating cooling

Contact our team if you’re unsure whether or not our sliding gate seat technology is right for your application.

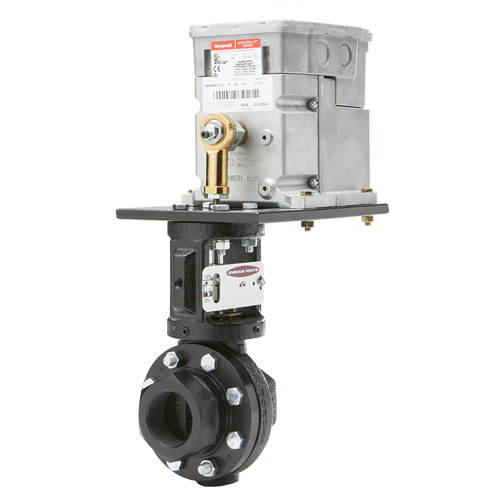

Mark 75 Series Wafer Style, Motor Operated Control Valve

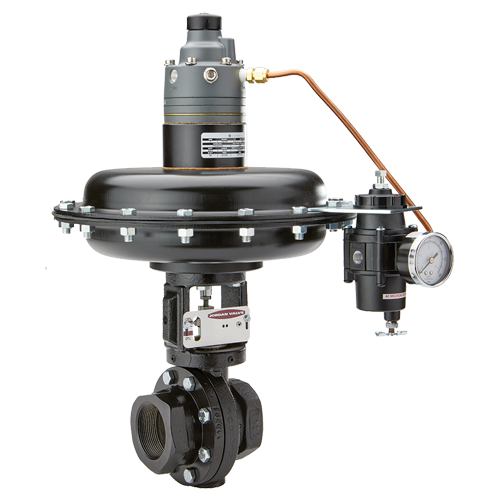

Mark 75 Series Wafer Style, Motor Operated Control Valve  Mark 60 Series Self-Operated Sliding Gate Pressure Reducing Regulator

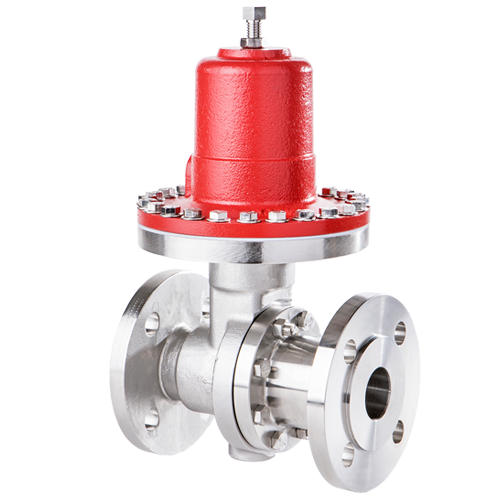

Mark 60 Series Self-Operated Sliding Gate Pressure Reducing Regulator  Mark 33 Series Boiler Feedwater Control Valve

Mark 33 Series Boiler Feedwater Control Valve  Mark 701 Series Sliding Gate Control Valve

Mark 701 Series Sliding Gate Control Valve  Mark 50 Series Self-Operated Sliding Gate Back Pressure Regulator

Mark 50 Series Self-Operated Sliding Gate Back Pressure Regulator