Precision Steam Control Valves for Superior Food Processing

Importance of accurate steam control in food processing

What types of steam are used in food processing?

Steam used in food processing can be separated into two general categories. “Plant Steam” or “Utility Steam” does not have direct contact with food, but is used in indirect, radiant heating or food drying. “Culinary Steam” is filtered, meets USDA and FDA requirements, and is used directly in the food preparation or in the cleaning of the food processing equipment. Culinary steam is broken down into further categories of purity where “Pure Steam” follows the most stringent regulations and can be used in organic food preparation. Lower purity “Clean Steam” may have certain USDA & FDA approved additives that help prevent corrosion in the boiler but are safe for human consumption.

How is steam used in food industry?

Steam is used in many food processing applications because it is an efficient and safe method of providing energy required for food production. Some food processes where steam is used include cooking, steam peeling, UHT and HTST pasteurization, drying, bottle washing and CIP/SIP cleaning. Each system will require a careful choice of steam type, as mentioned above, as well as steam control system. Cooking food, for instance, can be done in a vessel with steam heated jacketing using utility steam that does not contact the food. Cooking might instead use steam injection, which would require clean steam or pure steam delivered directly to the food. In either process, a precision steam control valve is required for a safe, reproducible cooking process.

Why is accurate steam control important in food processing?

Most importantly, accurate steam control during food processing ensures that the final food product is fit for human consumption: safe and tasty. Secondarily, precision steam control can decrease the cost of production and improve the manufacturer’s bottom line. Jordan Valve has a unique sliding gate technology in their steam control valves and steam temperature regulators that delivers superior performance, longer life, and fewer maintenance issues than other technologies. Jordan Valve is a Richards Industrials brand of valves designed for plant and utility steam control systems. Steriflow food & beverage, another Richards Industrials brand, manufactures 3A and sanitary valves for culinary steam control applications.

Case Study: Precision steam jacket control for seafood processing

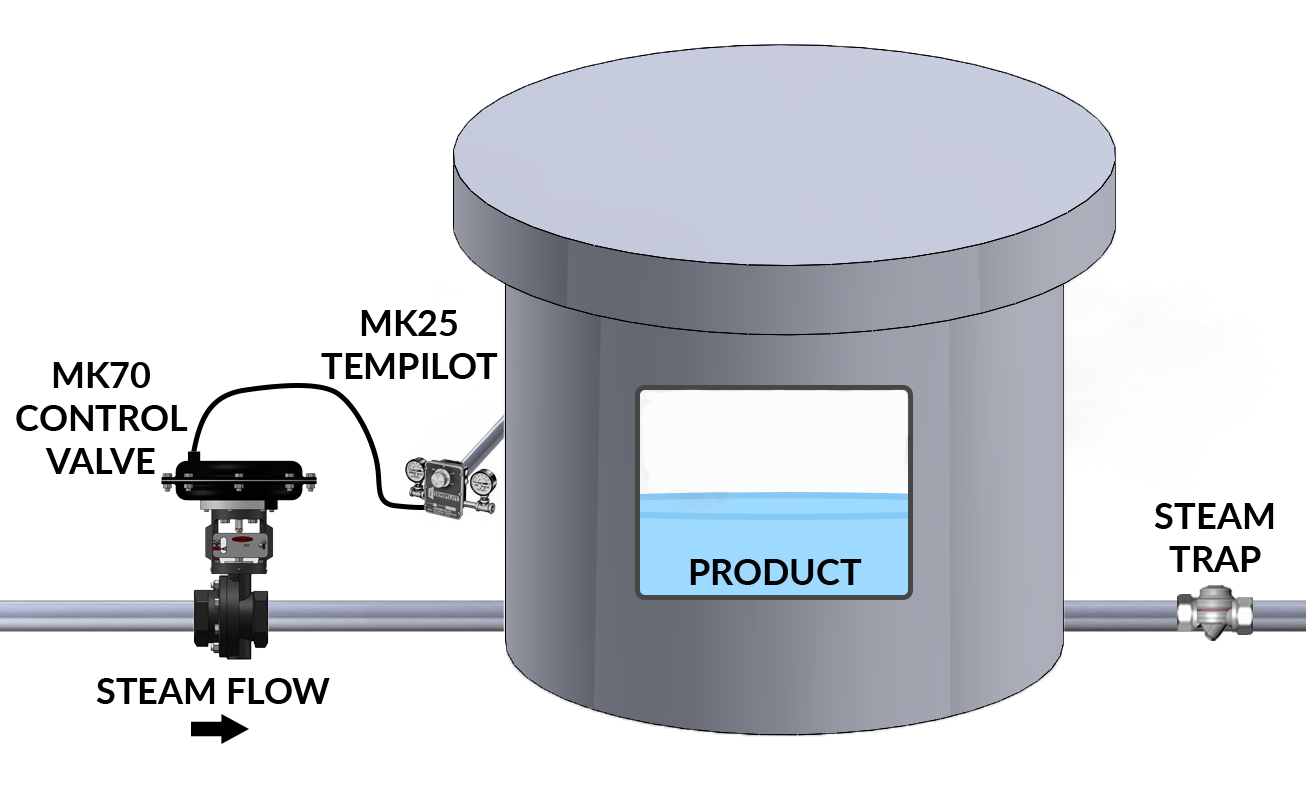

A seafood processing company approached Jordan Valve for help designing a system to thaw out batches of shrimp, 2000 lbs. at a time, in a slightly chilled tank. They required a steady and precise flow of utility steam delivered to the jacketed tank so the shrimp would defrost slowly. Too much steam would cook the shrimp and cause premature spoilage; too little steam would slow down the production process. The customer did not want a ‘filled system’ temperature regulator which has the potential to leak thermal fluid if there were a bulb failure.

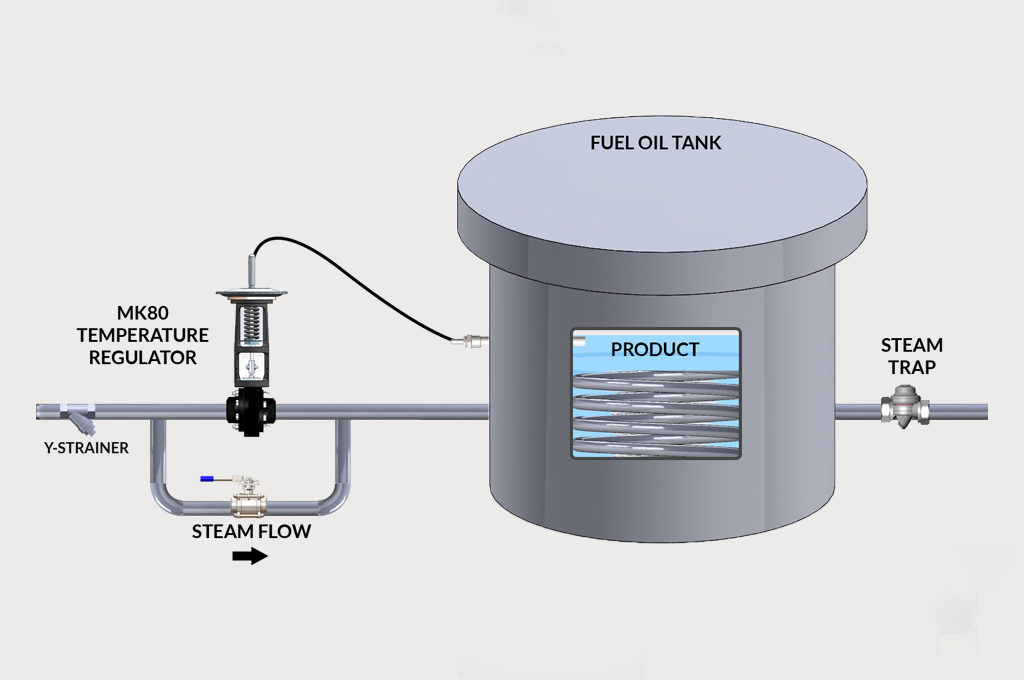

The solution was a Jordan Mark 70 pneumatically operated diaphragm control valve with sliding gate seat in conjunction with a Jordan Mark 25 temperature pilot controller. This valve was selected over competitive valves for its ability to provide precision low flow control and maintain the jacket and product temperature within the customer’s tight specification window. The Mark 25 bimetallic temperature pilot controller eliminated the customer’s concern about thermal fluid leaking into the product tank. A steam trap was installed at the exit of the tank jacket system. See drawing.

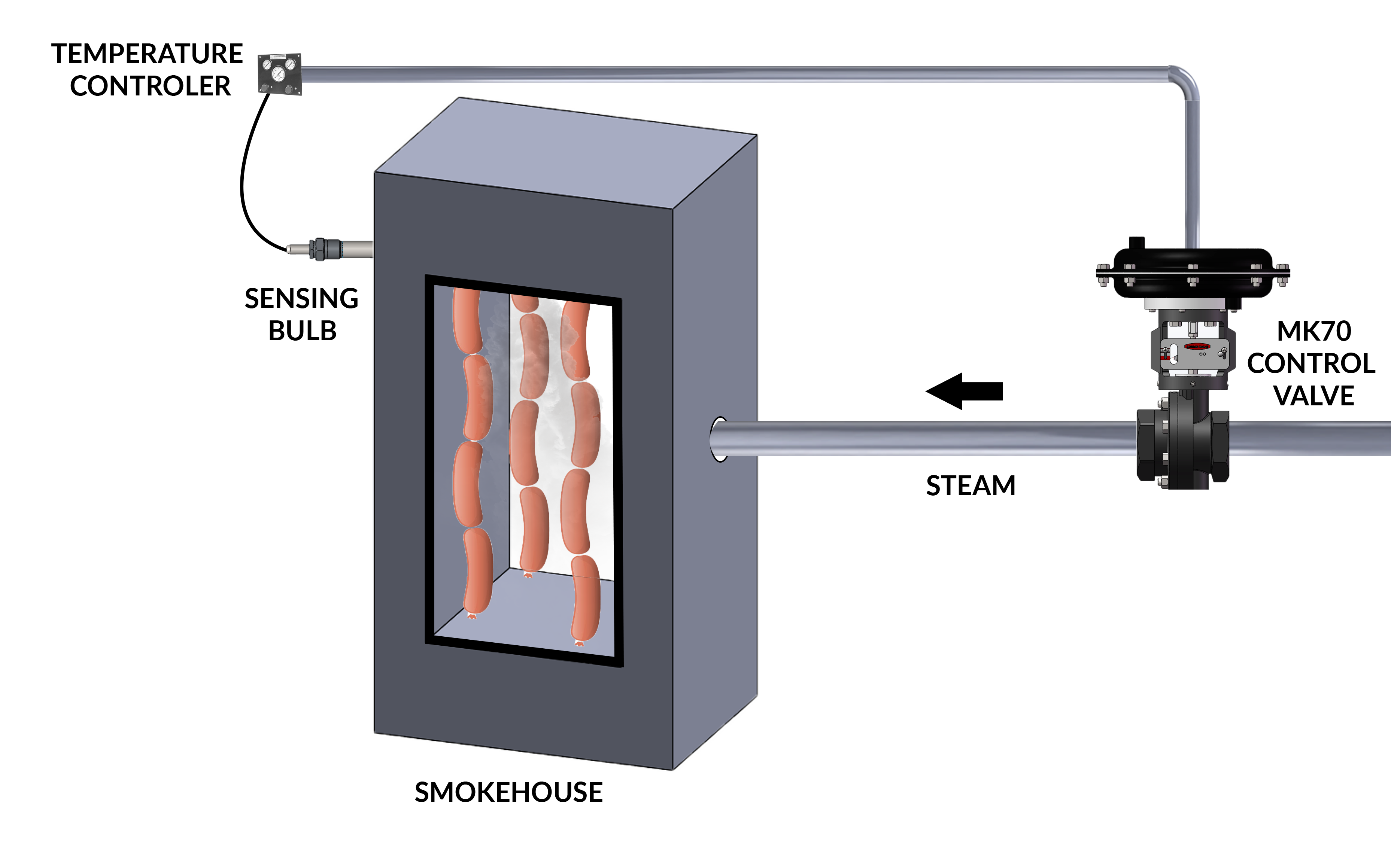

Case Study: Rapid steam control for smokehouse temperature control

A smokehouse customer requested a steam control valve for injecting steam into the smokehouse heating process. The system required a responsive valve that could gradually feed steam into the smokehouse heating element based on feedback from a temperature controller. When the temperature reached setpoint, the valve needed to close rapidly with a tight shut-off to avoid steam leaks. Any steam leaking into the system would raise the humidity in the smokehouse and possibly lead to product spoilage.

A Jordan Mark 70 control valve in conjunction with a Jordan Mark 25 temperature pilot controller was chosen for this application as well. The short stroke of the sliding gate seat provides rapid response resulting in precision steam delivery. It also has Class IV shut-off to prevent steam leaks. An added benefit for the customer is that it extends the life of the packing, reducing maintenance downtime.

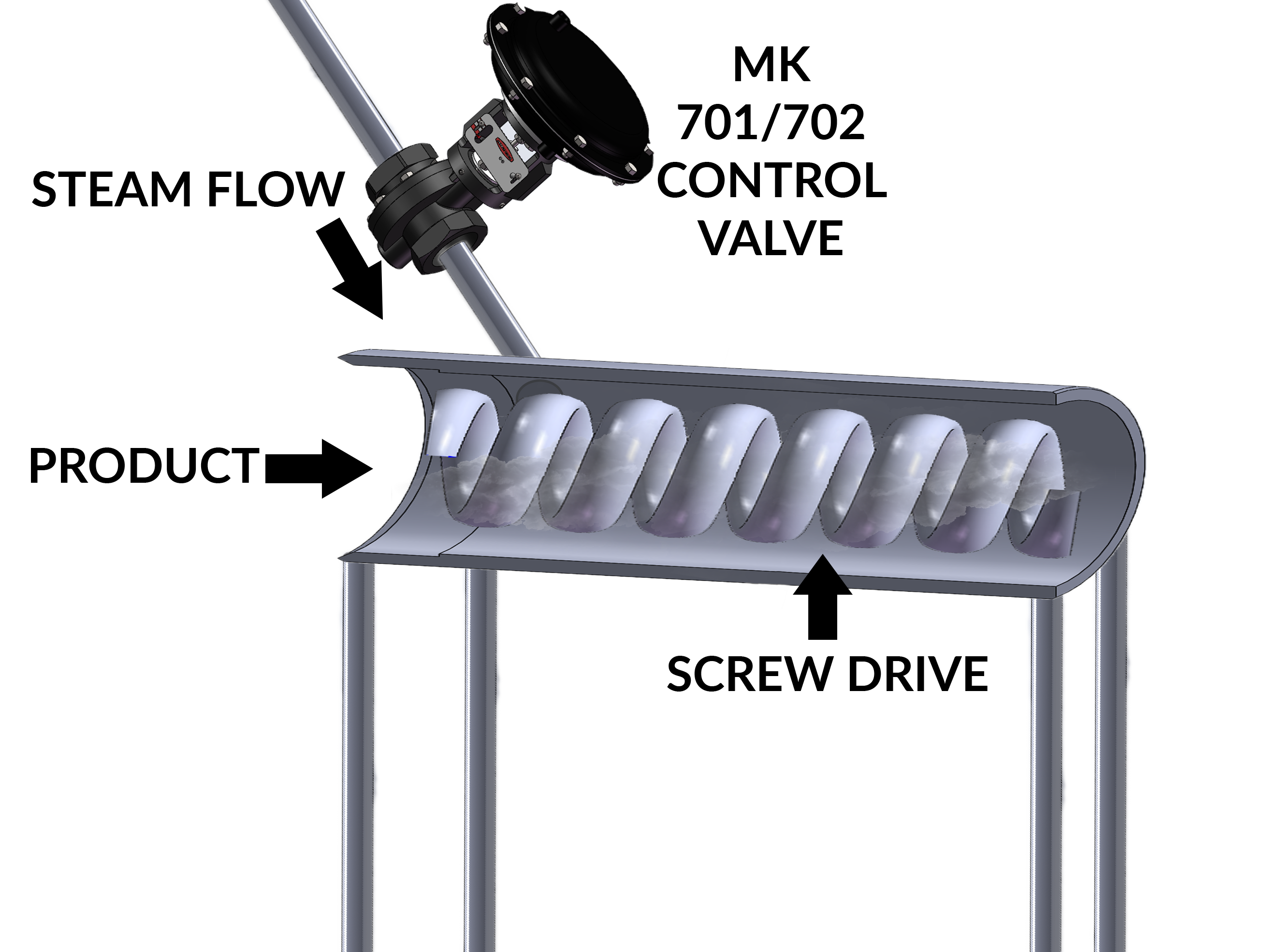

Case Study: Wide range steam control for steam peeling fruit and vegetables

Peeling fruit and vegetables is similar to blanching where steam is injected into the peeler as the product enters the system. Different steam injection rates are required for each fruit or vegetable to maintain food integrity. This customer required a control valve with a wide range of steam control rates due to the diverse variety of fruit and vegetables they process.

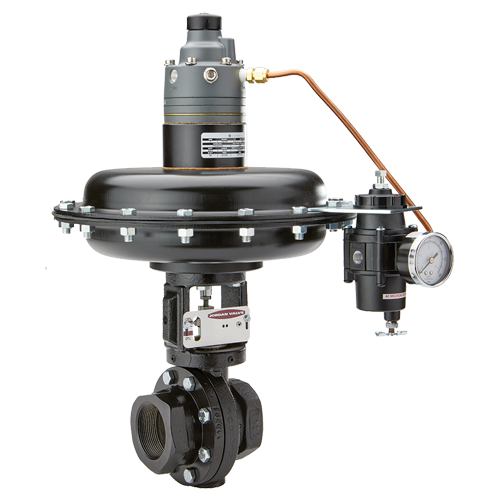

A Mark 701 was chosen for this application due to its high flow rates and wide rangeability. The Mark 701 high flow sliding gate control valve provides higher Cvs (Kvs), straight through flow and ease of maintenance. A side or top mounted positioner is available.

Jordan Valve and Steriflow Food & Beverage brands have an extensive selection of valves to control steam in your food processing applications.

Let us help you find the right valve for your application.

Related Resources

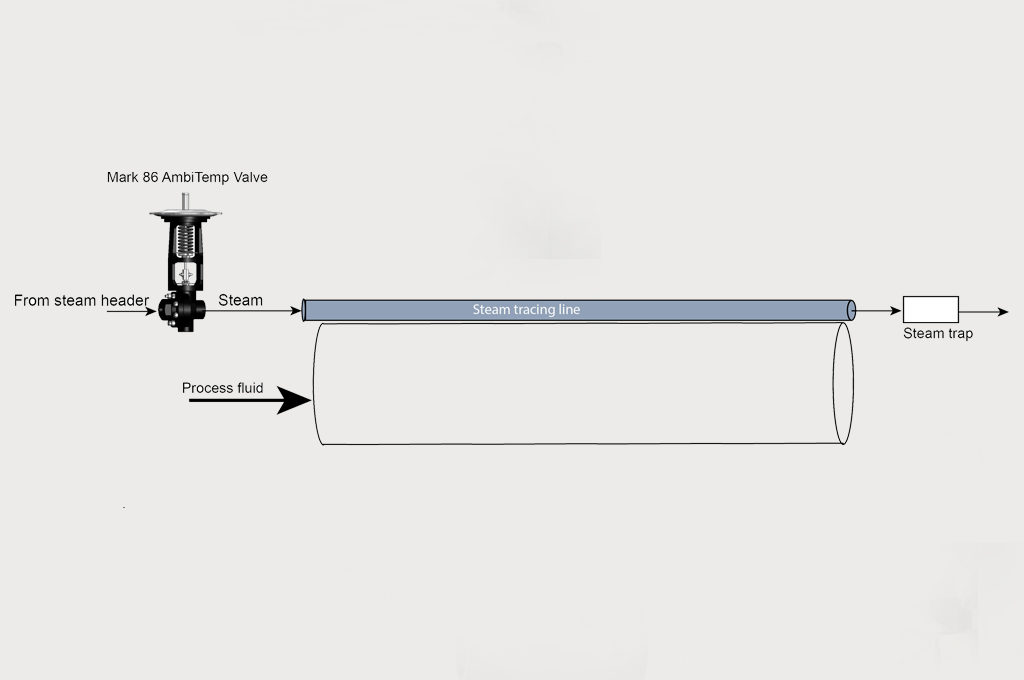

Steam Tracing for Pipe Protection

Mark 86 AmbiTemp regulator for worry-free control of steam trace lines

How Temperature Regulators and Control Valves Work

Using Self-Operated Temperature Regulators to Control Steam

Steam Temperature Control of Jacketed Tanks

Steam pressure control is vital for maintaining consistent tank jacket temperature

Steam Curing Cinder Blocks

Accurate steam control for precision autoclave dryer performance

Steam Sterilization

Jordan Valve sliding gate valves with Jorlon® diaphragms outlast in challenging steam sterilizing process

Precision Steam Control

Jordan Sliding Gate Valve for Precise, Efficient Steam Control

Steam Valve for Tire Curing Press

Jordan Valve sliding gate technology outperforms in challenging tire curing process

Better Steam Pressure Control Improves Drying for Coating Process

Jordan Mark 701 Sliding Gate Control Valves give Tighter Temperature Control, Faster Throughput

Boiler Feedwater Control

Jordan Mark 33 feedwater control valve maintains accurate level in boiler steam drum.

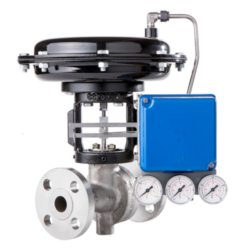

Mark 70 Series Sliding Gate Jorlon Diaphragm Control Valve

Mark 70 Series Sliding Gate Jorlon Diaphragm Control Valve  Mark 701/702 Series High Flow Sliding Gate Control Valve

Mark 701/702 Series High Flow Sliding Gate Control Valve  Mark 25 Series Tempilot Temperature Controller

Mark 25 Series Tempilot Temperature Controller