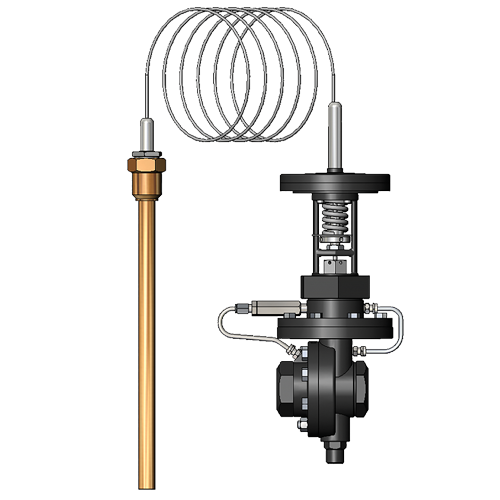

Mark 82 Series

Internal Piloted Temperature Regulators | Direct or Reverse Acting | Sliding Gate with Sensing Bulb

Reverse Acting: The internal pilot valve seats and the main valve seats are up and closed. As the process temperature rises, the fluid in the sensing bulb vaporizes to apply pressure to the pilot diaphragm thus opening the pilot valve. The upstream pressure passes through the pilot valve, through the pilot port opening the main valve to provide the required cooling action.

As the temperature sensed at the bulb drops, the pilot valve tends to close, shutting off pressure to the main valve's diaphragm. The lower spring closes the main valve as the pressure on the main diaphragm is bled off through the downstream port.

Direct Acting: operated as above except that the pilot valve is normally open and closes on an increase in temperature.

All Jordan’s pilot-operated temperature regulators feature the sliding gate technology:

- Straight-thru flow for reduced turbulence, longer life and quieter operation

- Short stroke for fast response and accurate regulation

- Easily interchangeable Cv’s

- Extended tight shutoff due to wear resistant coatings and overlap of seat closure area

Sizes: 1/2″ – 2″ (DN15 – DN50)

Body Material: Ductile Iron, Bronze

End Connection: Threaded, Flanged

Cv (Kv): up to 30 (25,8)

Seat Material: Jorcote on SST

Control Range: 10°F (-12°C) to 325°F (163°C)

Sliding Gate Valves

You will notice something different in many Jordan valves … the sliding gate seat. A remarkably simple concept that offers superior performance and benefits not found in traditional rising stem and rotary valves.

CRN Number

Mark 82/82FS: 1/2″ – 2″

ATEX Certified

Your List

Email List

Get A Quote

Explore our comprehensive range of Temprature Regulators engineered for diverse industrial applications.

Quick Quote

Know what you need and want a quote quickly? We can help! Fill out this form and we will get back to you shortly.