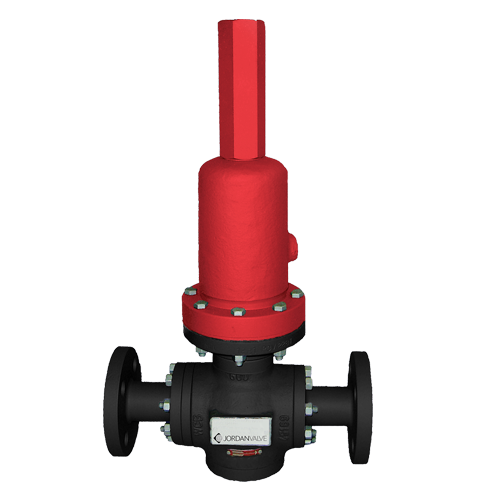

Pressure Reducing Regulators

The sliding gate pressure reducing regulators are ideal for steam, liquid and gas media. A variety of regulators are available including self-operated, high flow, differential, vacuum, air loaded and pilot operated.

Jordan Valve has a large line of pressure reducing regulators to meet many different specifications and applications, from self-operated to pilot-operated. The sliding gate pressure reducing regulators achieve levels of performance, reliability and accuracy that are not found in other valve designs. Request a quote today.

What is a pressure reducing regulator?

Pressure reducing regulators are used to maintain a set downstream pressure point by reducing the supply, also known as inlet pressure, of a fluid or gas to lower the outlet pressure.

Types Of Pressure Reducing Regulators We Carry

We have a variety of pressure reducing regulators available, including self-operated, high flow, differential, vacuum, air-loaded and pilot-operated. Many of our pressure reducing valves have the sliding gate technology which offers precise control in a variety of applications.

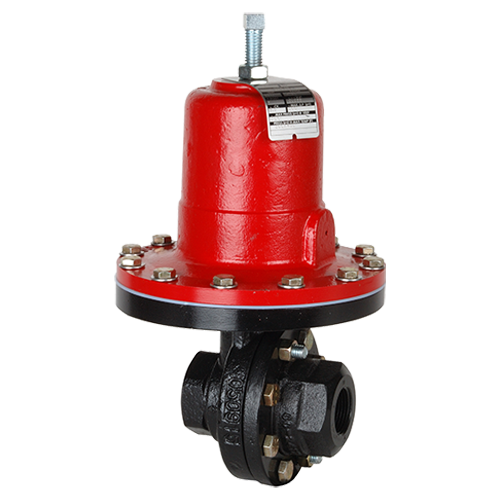

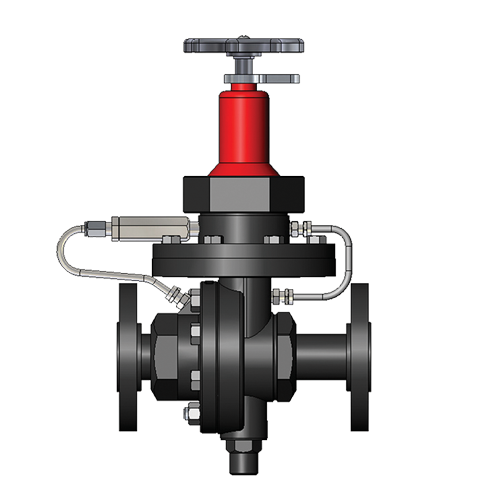

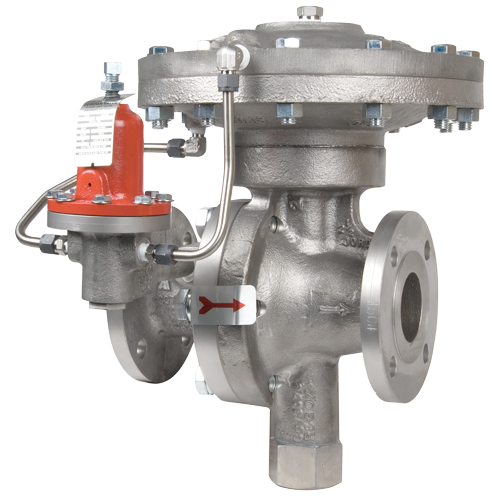

Mark 60 Series ⟶

Self-Operated Sliding Gate Pressure Reducing Regulator; Quick Ship Available

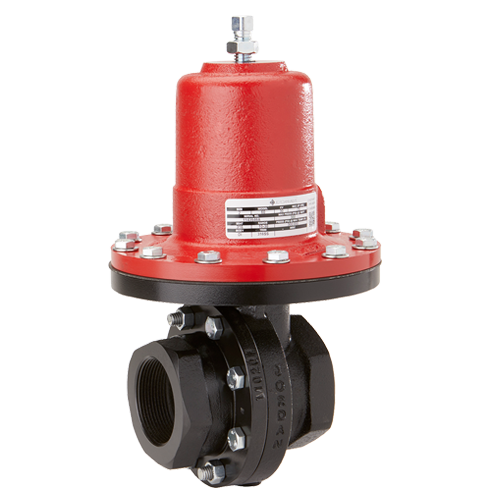

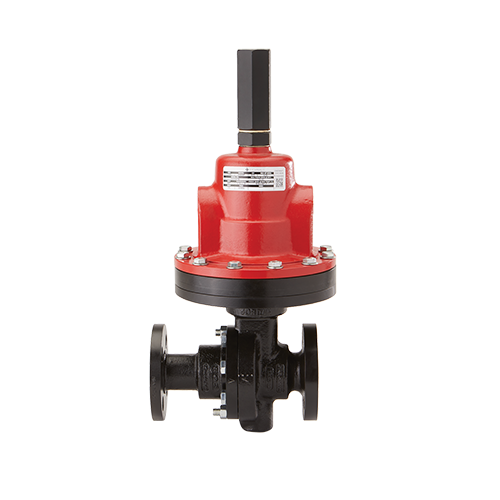

Mark 601/602 Series ⟶

Self-Operated, High Flows

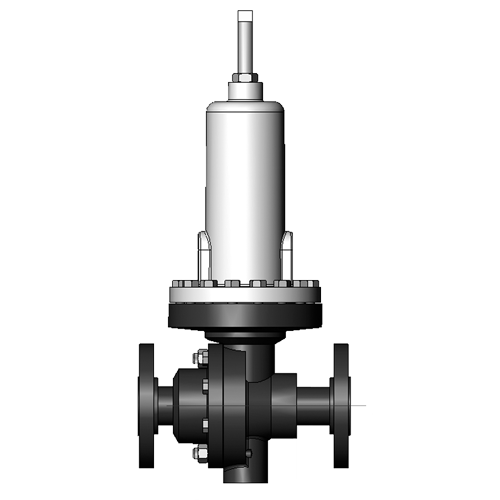

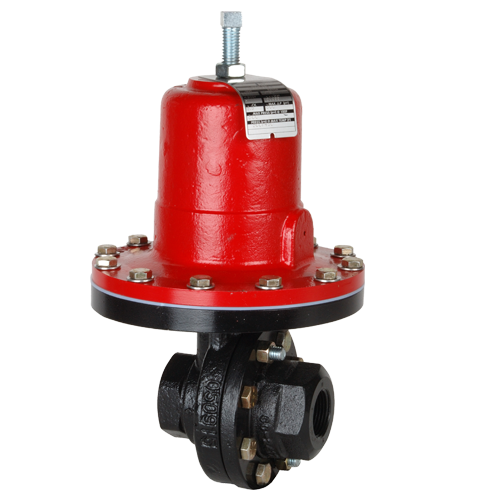

Mark 60HP Series ⟶

High Pressure Regulator

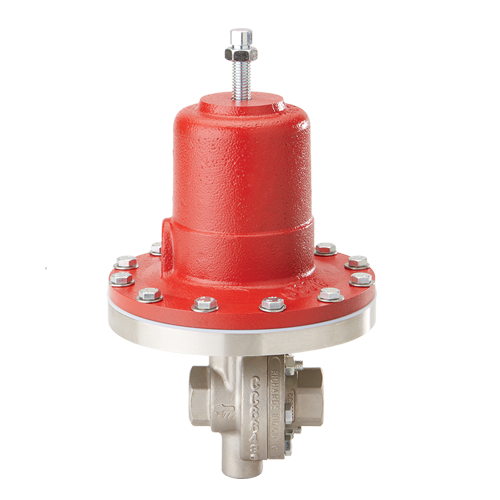

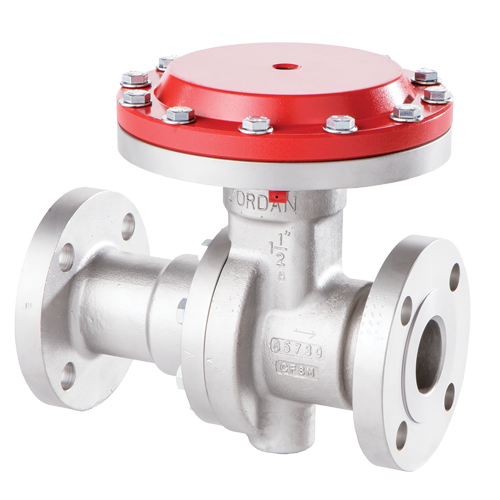

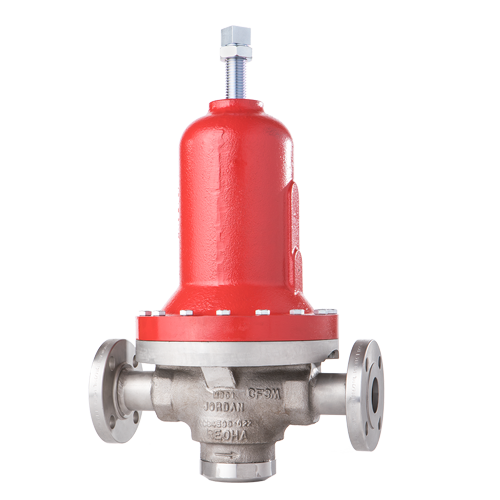

Mark 61 Series ⟶

High Sensitivity

Mark 62 Series ⟶

Internally Piloted Regulator

Mark 63/64 Series ⟶

Differential Pressure Regulators; Sliding Gate Seat; 1/4″ – 2″ (DN8 – DN50);

Mark 65 Series ⟶

Downstream Vacuum Regulator, Sliding Gate Seat; 1/2″ – 2″ (DN15 – DN50)

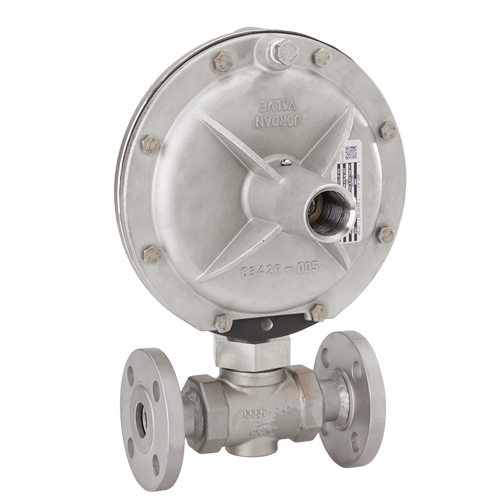

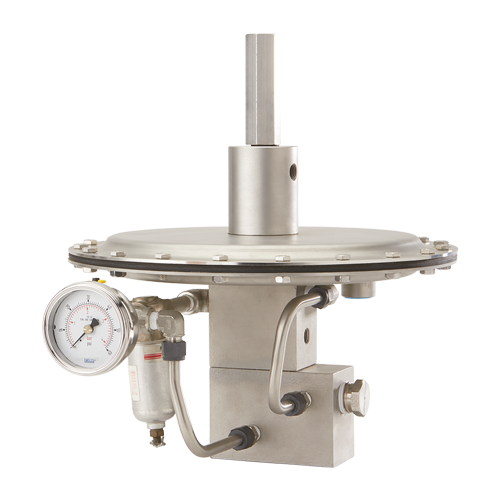

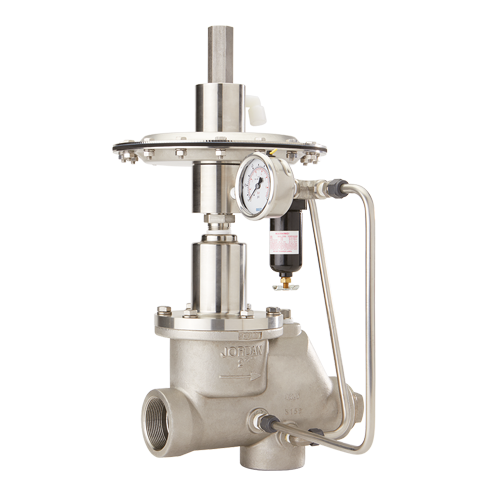

Mark 66/660 Series ⟶

Air Loaded Pressure Reducing Regulator, Sliding Gate Seat, High Accuracy

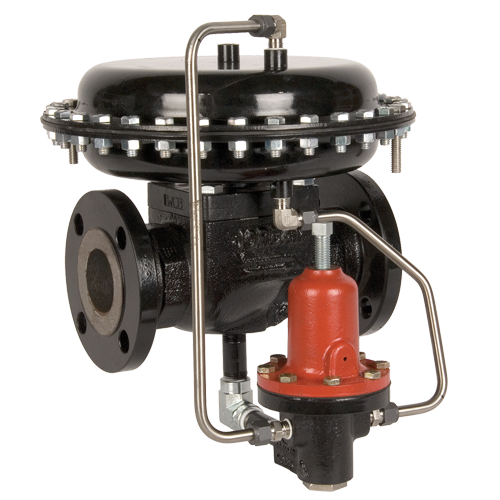

Mark 67/69 Series ⟶

Pilot-Operated, High Flow

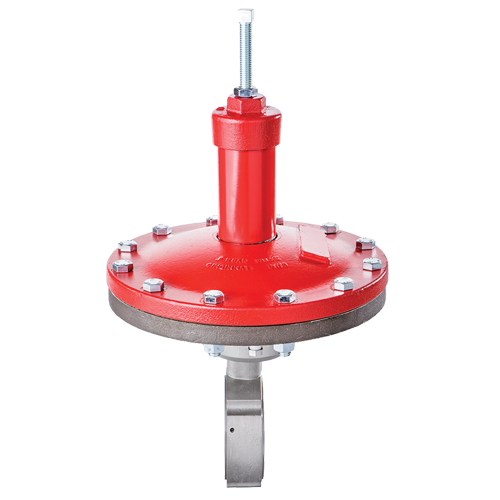

Mark 675 Series ⟶

Wafer Style, Jorlon Diaphragm

Mark 68G Series ⟶

Pressure Reducing Globe Valve, High Capacity, Accurate; Sizes: 1/4″ – 2″ (DN8 – DN50)

Mark 68HP Series ⟶

High Pressure Regulator

Mark 686G Series ⟶

Air-Loaded, Globe Trim, ANSI IV or VI

Mark 608 Series ⟶

Direct Operated Tank Padding Regulator or

Gas Pressure Reducing Regulator for Low Pressures

1-1/2" - 2" (DN40 - DN50)

Mark 608BP Series ⟶

Direct Operated Tank Padding Regulator or

Gas Pressure Reducing Regulator for Low Pressures

3/4" - 1" (DN20 - DN25); Balanced Plug - Good for High Inlet Pressures

Mark 608IS Series ⟶

Direct Operated Tank Padding Regulator or

Gas Pressure Reducing Regulator for Low Pressure

3/4" - 1-1/4" (DN20 - DN32); Internal Sensing - Good for Low Inlet Pressure

Mark 627 Series ⟶

Self-Operated Pressure Reducing Gas Regulator, High Inlet Pressure; 3/4″ - 2″ (DN20 - DN50)

Mark 630 Series ⟶

Gas Regulator, Self-Operated, High Inlet Pressure

Mark 687 Series ⟶

Piloted Pressure Reducing Regulator for

Critical Low Pressure, High Flow Applications

1-1/2" - 2" (DN40 - DN50); Balanced Plug

Mark 688 Series ⟶

Piloted Tank Padding Regulator or

Gas Pressure Reducing Regulator for Low Pressures

1" - 2" (DN25 - DN50)

Mark 695 Series (3/4″ – 1″) ⟶

Piloted Tank Padding Regulator

3/4", 1" (DN20, DN25); External Pilot

Mark 695 Series – 2″ ⟶

Piloted Tank Padding Regulator

2" (DN50); Internal Pilot

Mark 695X Series ⟶

Direct Operated Tank Padding Regulator

1/2" - 3/4" (DN15 - DN20)

Mark 608BPM Series ⟶

Pressure Regulators

Mark 608MM Series ⟶

Pressure Regulators

Mark 608UBAN Series ⟶

Pressure Regulators

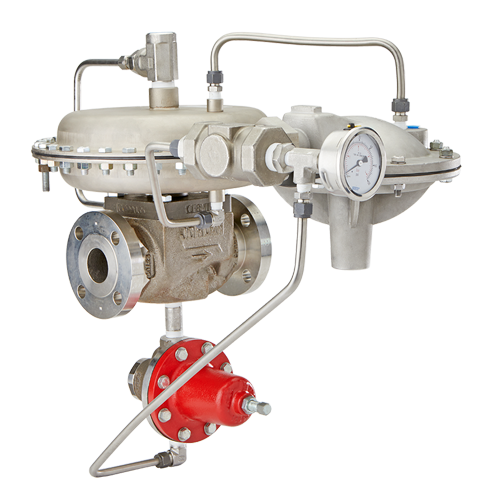

Mark 6127 Series ⟶

Piloted, Liquid Pressure Regulating Valves

Y-Type Strainers ⟶

Line Strainers

Your List

Sanitary Products

Email List

Get A Quote

For assistance choosing the right pressure reducing regulator for your application, use our sizing software program or contact your local representative.

How do pressure reducing regulators work?

Pressure reducing regulators monitor the downstream pressure and do not need any external power or air source to operate. Instead, they work by force balance. There are 4 main parts to a pressure regulator:

- Set screw

- Spring

- Diaphragm

- Plug

The compressed spring and diaphragm are the two opposing forces and the plug acts as the balance between the two. The set screw is used to show the regulator how much pressure we want by turning it to compress the spring. A compressed spring generates a force causing it to push down. This opens the plug and results in more flow (of water, air, or other media).

If there is a change in the controlled pressure, the diaphragm will be forced to move. For example, the pilot plug will allow upstream gas to flow under the diaphragm where the pressure is controlled by the position of the plunger. If any pressure exceeds your set point, the pressure below the diaphragm will be pushed up, closing off the pilot plug.

Benefits Of Using Pressure Reducing Regulators

Some benefits of using a pressure reducing regulator include:

- Pressure regulators are much faster in response time because there is no need to go back to the controller.

- Regulators can respond immediately to changes in the controlled pressure.

- Regulators are usually easier to maintain and are cheaper to install.

Applications For Pressure Reducing Regulators

Our sliding gate pressure reducing regulators are ideal for steam, liquid and gas media applications. However, we also see use cases for the following applications:

- For the food & beverage industry

- For high-pressure applications

- To reduce pressure

- For fuel and oil burner control

- For fuel and oil atomization

- For natural gas applications

- For precise pressure control for low-pressure tank blanketing

Contact us for more information on the different applications of our pressure reducing regulators.

Frequently Asked Questions

1. How do I choose a pressure reducing regulator?

How you choose a pressure reducing regulator depends on why you need it. There are five things you need to have to choose the right pressure reducing regulator with the right flow coefficient (Cv):

- Upstream pressure: The supply pressure or inlet pressure going into the valve.

- Outlet/Downstream pressure: The outlet is the pressure downstream of the regulator.

- Pressure differential: The difference between upstream and downstream pressure is the pressure differential.

- Flow range: Used so you don’t undersize or oversize the valve.

- Temperature

- Fluid type: Is it a liquid, gas, or steam? There is a big difference between saturated steam and superheated steam.

After you have correctly sized your regulator, you’ll then need to know the line size, material, type of connection, whether it’s a shutoff or not, and if it’s either direct or pilot-operated.

However, the most important things you’ll need to know in selecting a regulator for a specific application are what the flowing media is and what the desired flow rate is, and what the inlet and outlet pressures will be.

We have sizing software available to help with sizing a regulator so you know exactly what you need.

2. Does a pressure regulator reduce flow?

No, a pressure reducing regulator won’t reduce flow, you’ll need a control valve for that.

3. What size pressure reducing valve do I need?

If you’re not sure what size of pressure reducing valve you need, don’t hesitate to reach out to our experts for help. We also have sizing software available to help with sizing a regulator.