Industrial Control Valves

Jordan Valve has a large line of industrial control valves to meet more specifications and applications. From sliding gate control valves to globe, wafer, motor operated, electric, bellows seal and angle body on/off control valves.

What is an industrial control valve?

Industrial control valves are used in many different industries (primarily oil and gas) to control operating conditions such as flow, pressure, temperature, and liquid levels.

Industrial Control Valve Design

Every industrial control valve has a:

- Bonnet: The top of the valve that houses the diaphragm and spring.

- Spring: To keep tension on the stem to keep the valve in position.

- Actuator: To receive a signal from the controller and adjust valve position.

- Stuffing Box Assembly: This provides a seal that prevents leakage.

- Travel Indicator: A visual indication of the valve’s position.

Stem & Seal: To block the flow through the valve.

Find The Right Control Valve For Your Application & Industry

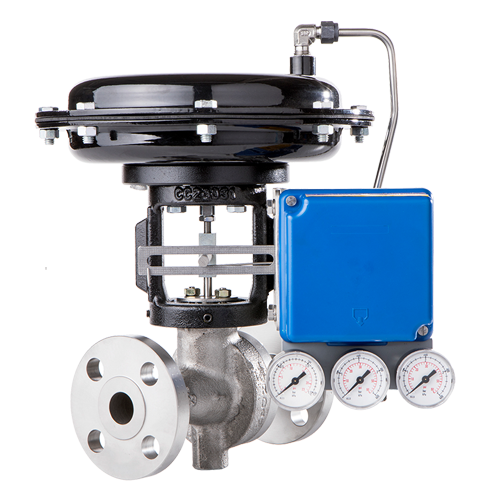

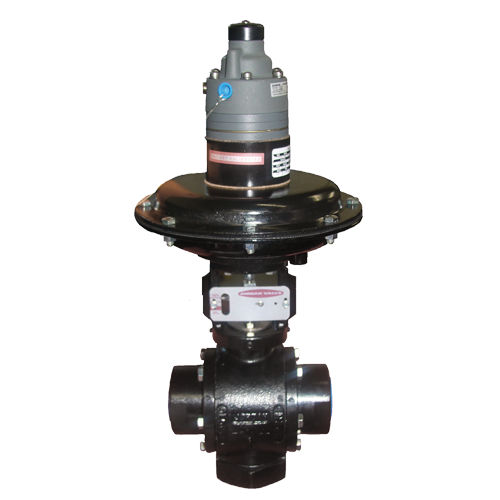

Mark 70 Series ⟶

Sliding Gate Jorlon Diaphragm Control Valve

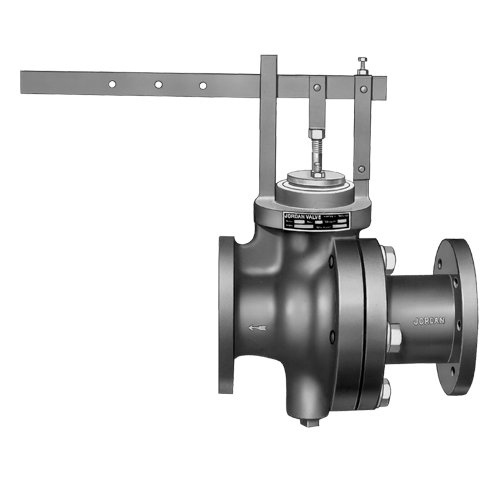

Mark 701/702 Series ⟶

Sliding Gate Control Valve for High Flow, Higher Cv's (Kv's)

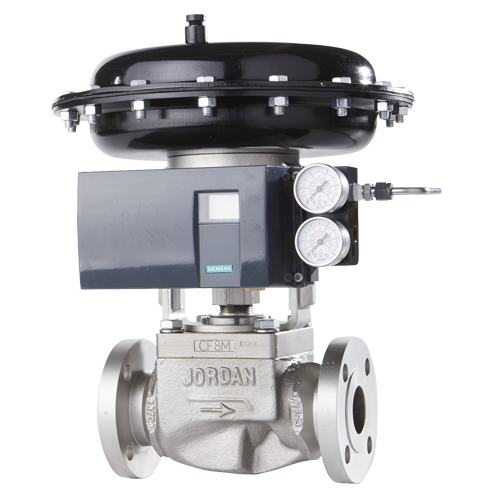

Mark 78 Series ⟶

Globe Style, Accurate Performance

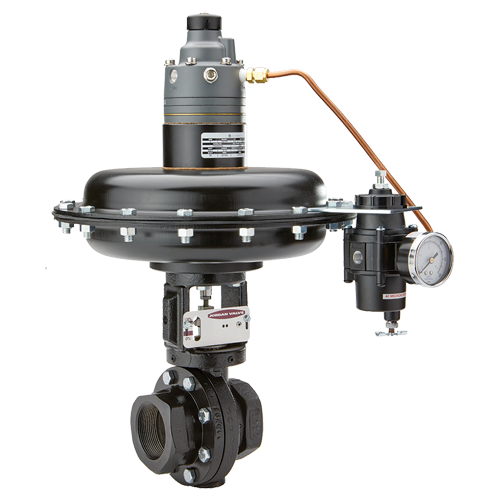

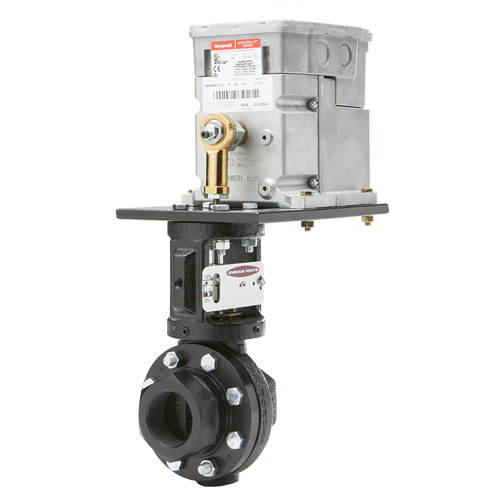

Mark 75 Series ⟶

Wafer Style, Motor Operated, Very Precise

Mark 75HW Series ⟶

Wafer Style, Hand Operated, Precise Adjustment

Mark 75MV Series ⟶

Wafer Style, Motor Operated Control Valve; Sliding Gate; 1″ - 8″ (DN25 - DN200)

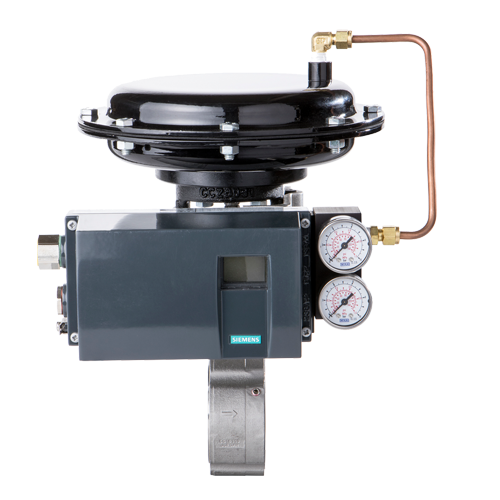

Mark 75PTP Series ⟶

Piston Operated with Smart Positioner

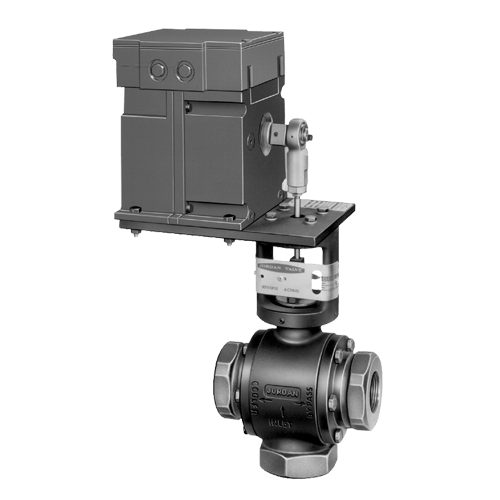

Mark 79/79MX Series ⟶

Three-Way, Bypass or Mixing

Mark 33 Series ⟶

Boiler Feedwater Control Valve; Motor Operated Sliding Gate; 1/4″ – 2″ (DN8 – DN50)

Mark 37 Series ⟶

Motor Operated Control Valve With Electronic Linear Actuator; 1/4″ – 6″ (DN8 – DN150)

Mark 39 Series ⟶

Motor Operated Three Way

Mark 74 Series ⟶

Bellows Seal

Mark 40/46 Series ⟶

Float/Lever Operated Level Control Valves; Sliding Gate; 1/4″ – 6″ (DN8 – DN150)

Your List

Sanitary Products

Email List

Get A Quote

Types Of Industrial Control Valves We Carry

Some examples of the different types of control valves we carry include:

- Sliding gate valves

- Angle Valves

- Globe Valves

- Wafer Style Sliding Gate Valves

- Electric Valves

- Motor Operated Valves

- Bellow Seals Valves

For assistance choosing the right control valve for your application, please use our sizing software program or contact your local representative.

How do industrial control valves work?

Industrial control valves are essentially powered by a control loop. They have a controller that signals them how to respond. A control valve can’t work by itself, it must receive a signal from an outside source, like an actuator or controller. A control valve is power-operated and it is used to control fluid flow by varying the size of the flow passage as directed by the signal in the controller. Control valves control flow, pressure, and temperature of the media. There are different variables that are measured for control, these include:

- Flow

- Liquid Level

- Temperature

- Pressure

Control valves come in really large sizes whereas pressure regulators are much smaller. Control valves can also have severe service trim material so they can operate in harsh environments. Because control valves have a controller, maintenance can look at the diagnostics and see if the valve is working optimally.

Benefits Of Using Industrial Control Valves

Industrial control valves have become a popular choice for a number of reasons including:

- They are easy to install which saves considerable time and effort.

- They can be operated automatically which removes the need for an operator to open and close the valve.

- They can help limit obstruction and eliminate the possibility of clogging.

- The Sliding Gate control valves can reduce waste which makes them a more environmentally friendly option.

Applications For Industrial Control Valves

Here are some most common applications of our industrial control valves in different industries:

- Air, oil, and gas industries

- Food and beverage industries

- Steam services

- Flow control services

- Mixing and diverting applications

- Water steam circuit

- Zero fugitive emissions requirements

- Water and float level control

- Steam curing cinder blocks applications

- Precision steam control applications

- Tire curing processes

Contact us for more information on the different applications of our industrial control valves.

Frequently Asked Questions

1. Which type of control valve is most commonly used in each industry?

One of the most common control valves used in each industry is globe valves. For globe valves, there are three different plugs that affect the flow or opening characteristics:

- Fast opening

- Linear

- Equal percentage

The equal percentage globe valve is our most popular. It essentially has a plug that incrementally increases the flow rate by a certain percentage from the previous flow.

However, the type of control valve you need depends on the size of the pipe, the overall pressure of the system, the flowing media, process conditions, and other factors. Get in touch with us today for help selecting the right control valve.

Ball valves can also be considered control valves which you can find in our Marwin Valve line.

2. How does a control valve affect the control loop?

The control valve controls the fluid flow as it goes through the loop. The signal in the controller tells the control valve how much or little of the fluid should go through the system.

3. I need a reference guide showing the quick specs of sliding gate control valves?