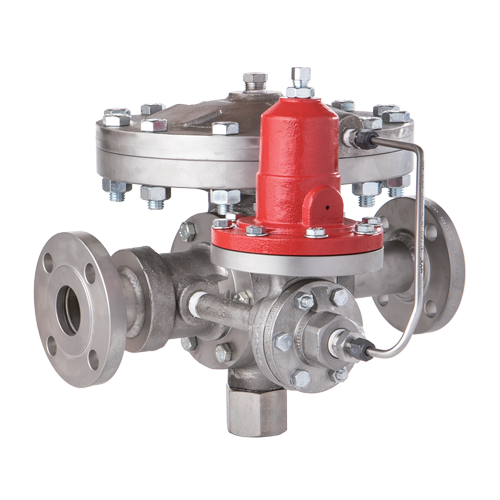

Mark 57 Series

Pilot-Operated, Superior Accuracy

The Mark 57 Series pilot-operated back pressure regulator is designed to accurately control pressure to 90% of its rated flow capacity with only a small deviation from setpoint. The Mark 57 provides accuracy that approaches that of controller-operated valves and should be considered on most critical applications.

- High turn-down ratios – Up to 50:1

- Versatile Application – Use on steam, air, gas, liquids, or chemicals

- Sliding gate seats provide straight-through flow for reduced turbulence, quiet operation, fast response, and tight shutoff

Sizes: 1/2″ – 6″ (DN15 – DN150)

Cv (Kv): up to 395 (up to 340)

Diaphragm: Stainless Steel

Setpoint: 10 to 185 psi (0,7 to 12,8 bar)

Body Material: Ductile Iron, Carbon Steel, Stainless Steel, Cast Iron

End Connection: Threaded, Flanged, Socket Weld, Butt Weld

Benefits of the Sliding Gate

Read on to learn the benefits of owning sliding gate regulators and control valves.

Sliding Gate Infographic

Download this infographic on the benefits of the sliding gate in regulators and control valves.

Sliding Gate Valve Overview

Watch this video for an overview of Sliding Gate Pressure Regulators and Control Valves

Sliding Gate Videos

Explore our collection of videos dedicated to sliding gate valves, particularly designed for efficient operation in steam and high temperature applications.

- EC Declaration of Conformity/PED:

Mark 57: 1-1/4″ – 6″ - CRN (Canadian Registration Number)

Mark 57: 1/2″ – 6″

Your List

Email List

Get A Quote

Related Products

Y-Type Strainers

Line Strainers

Quick Quote

Know what you need and want a quote quickly? We can help! Fill out this form and we will get back to you shortly.