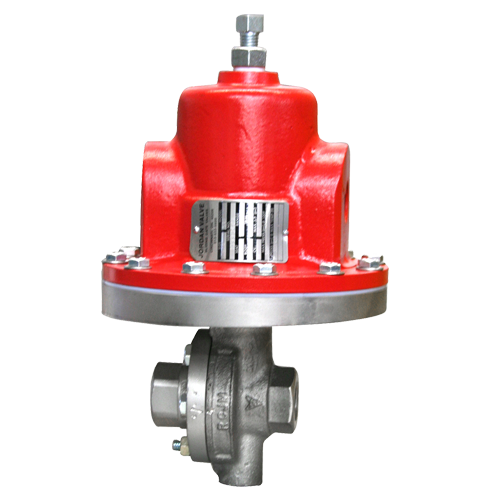

Mark 53/54 Series

Differential, Jorlon Diaphragm

The Mark 53 is designed to maintain inlet pressure at a set differential pressure over the signal pressure loaded on the diaphragm. The Mark 54 provides the same flow capacity but with less offset in controlled pressure due to a larger diaphragm. It can be used for both differential and remotely adjusted applications. A negative differential version is also available.

- Maintains a constant differential between the inlet pressure and the pressure loaded to the top of the diaphragm

- Straight-through flow for reduced turbulence and quiet operation

- Short stroke for fast response and accurate regulation

- Easily interchangeable CV’s

- Tight shutoff

Sizes: MK53″ 1/4″ – 2″ (DN8 – DN50); MK54: 1/4″ – 3/4″ (DN8 – DN20)

Cv (Kv): up to 30 (up to 25,8)

Diaphragm: Jorlon, Stainless Steel, Buna-N, Viton

Setpoint: MK53: 0.5 – 150 psi (0,03 to 10,3 bar); MK 54: 0.5 to 170 psi (0,03 to 11,7 bar)

Body Material: Ductile Iron, Bronze, Carbon Steel, Stainless Steel

End Connection: Threaded, Flanged, Socket Weld, Butt Weld

Options: Double Diaphragm, Flow through Dome, and Handwheel

Benefits of the Sliding Gate

Read on to learn the benefits of owning sliding gate regulators and control valves.

Sliding Gate Infographic

Download this infographic on the benefits of the sliding gate in regulators and control valves.

Sliding Gate Valve Overview

Watch this video for an overview of Sliding Gate Pressure Regulators and Control Valves

Sliding Gate Videos

Explore our collection of videos dedicated to sliding gate valves, particularly designed for efficient operation in steam and high temperature applications.

- EC Declaration of Conformity/PED:

Mark 53: 1-1/4″ -2″

Mark 54: 1/4″ – 3/4″ - CRN Number

Mark 53: 1/4″ – 2″

Mark 54: 1/4″ – 3/4″ - ATEX Certified

Your List

Email List

Get A Quote

Related Products

Y-Type Strainers

Line Strainers

Quick Quote

Know what you need and want a quote quickly? We can help! Fill out this form and we will get back to you shortly.