Back Pressure Regulators

The sliding gate back pressure regulators are ideal for steam, liquid and gas media. A variety of regulators are available including self-operated, high flow, differential, vacuum, air loaded and pilot operated.

Jordan Valve has a large line of back pressure regulators that meet many different specifications and applications, from self-operated to air-loaded to pilot-operated. The sliding gate back pressure regulators achieve levels of performance, reliability, and accuracy that are not found in other valve designs.

Our sliding gate back pressure regulators are ideal for steam, liquid, and gas applications.

What is a back pressure regulator?

A back pressure regulator is a device that maintains a defined pressure upstream of its own inlet. In other words, it controls the inlet pressure while allowing any excess pressure to vent through the regulator.

Types Of Back Pressure Regulators We Carry

We have a wide variety of back pressure regulators available including self-operated, high flow, differential, vacuum, air loaded, and pilot-operated. Many of our back pressure regulators have sliding gate technology which offers precise control in a variety of applications.

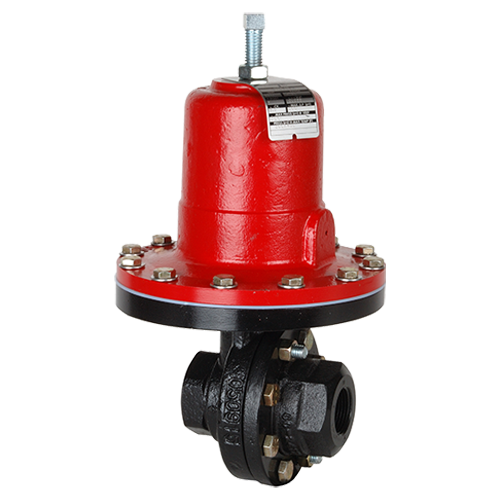

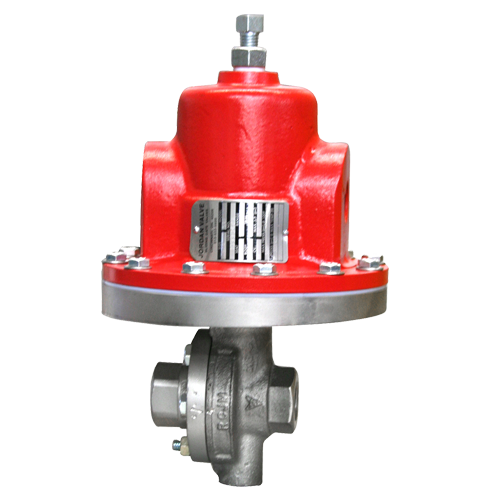

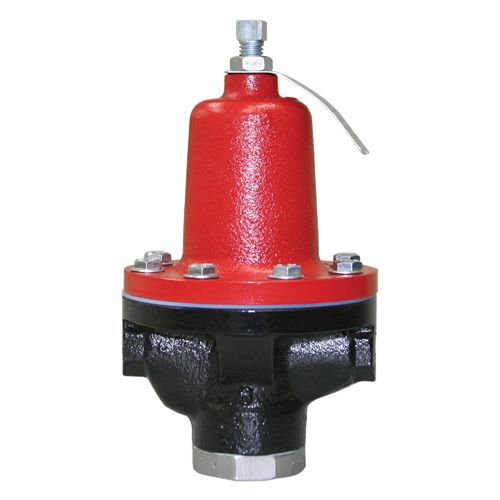

Mark 50 Series ⟶

Self-Operated Sliding Gate Back Pressure Regulator; Quick Ship Available

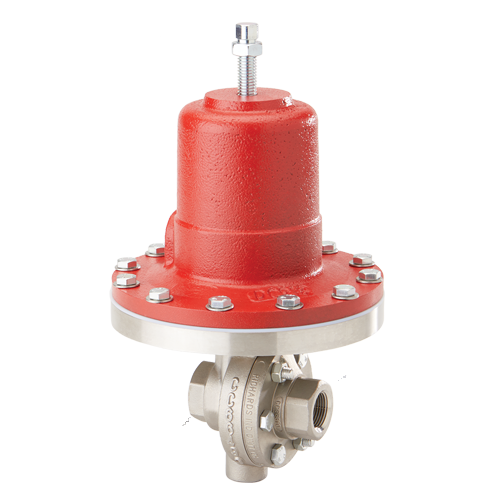

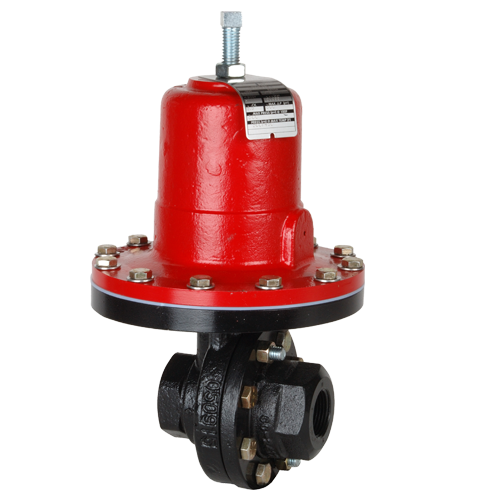

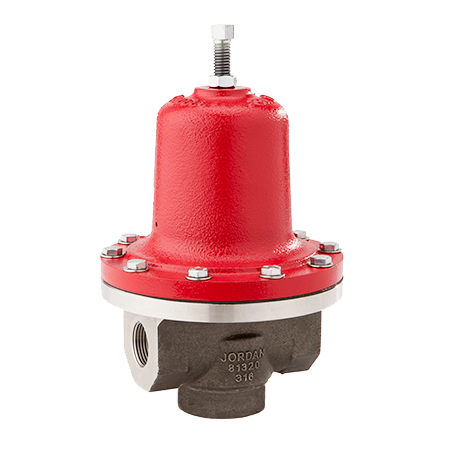

Mark 501/502 Series ⟶

High Flow Back Pressure Regulator; Sliding Gate; 1-1/2″ – 2″ (DN40 – DN50)

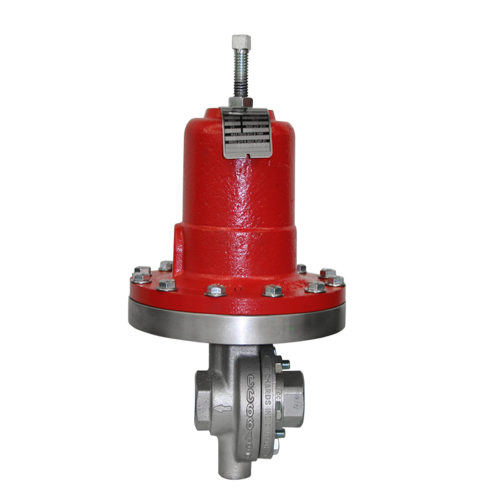

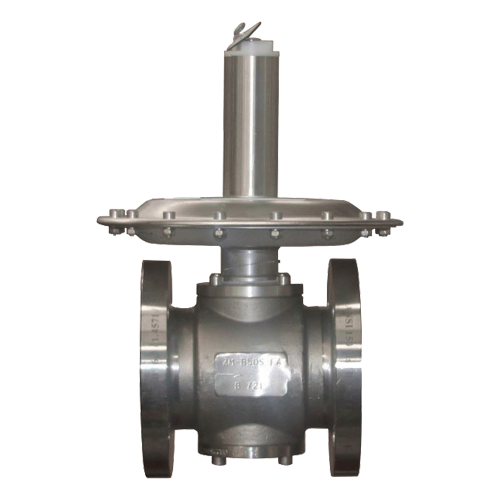

Mark 50HP Series ⟶

High Pressure Back Pressure Regulator; Up to 450 psi (31 bar); 1/4" - 4" (DN8 - DN100)

Mark 51 Series ⟶

High Sensitivity

Mark 52 Series ⟶

Internally Piloted

Mark 53/54 Series ⟶

Differential, Jorlon Diaphragm

Mark 55 Series ⟶

Upstream Vacuum, Jorlon Diaphragm

Mark 56/560 Series ⟶

Dome Loaded, High Accuracy

Mark 57 Series ⟶

Pilot-Operated, Superior Accuracy

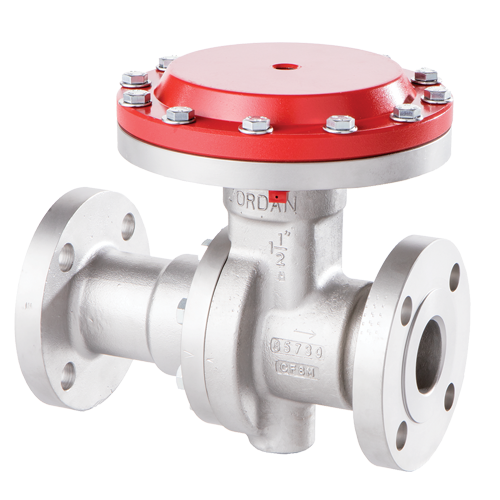

Mark 575 Series ⟶

Wafer Style, Jorlon Diaphragm

Mark 58FT/A Series ⟶

Cage Trim, Dual Inlet & Outlet for Through-Flow

Mark 58G Series ⟶

Globe Style, Back Pressure Regulating Valve

Mark 586FT/586A Series ⟶

Dome Loaded

Mark 508 Series ⟶

Direct Operated Tank De-pad Regulator or

Gas Back Pressure Regulator for low pressures

3/4″ – 2″ (DN20 – DN50)

Mark 518 Series ⟶

Direct Operated Tank De-pad Regulator or

Gas Back Pressure Regulator for low pressures

1", 2", 4" (DN25, DN50, DN100)

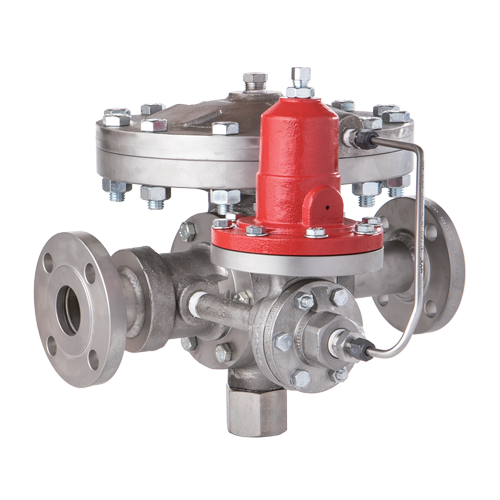

Mark 5108 Series ⟶

Piloted Industrial Back Pressure Regulator, Sizes: 1-1/4″ – 24″

Mark 508MM Series ⟶

Self-Operated

Y-Type Strainers ⟶

Line Strainers

Your List

Sanitary Products

Email List

Get A Quote

For assistance choosing the right back pressure regulator for your application, use our sizing software program or contact your local representative.

How do back pressure regulators work?

A back pressure regulator is a valve that maintains a defined pressure upstream of its own inlet. When fluid pressure at the inlet of the back pressure regulator exceeds the setpoint, the regulator opens to relieve the excess pressure. The back pressure regulator continually adjusts its position to keep the inlet pressure at the desired setpoint.

In the normally closed position, upstream pressure is sensed underneath the diaphragm. As upstream pressure increases above the setpoint, the pressure of the service overcomes the spring force and begins opening the valve. This bleeds off the pressure on the upstream pressure side and maintains the constant upstream pressure.

Benefits Of Using Back Pressure Regulators

Some of the benefits of using back pressure regulators include:

- Straight-through flow where turbulence is reduced and superior trim life is achieved.

- Our sliding gate design provides exceptional low flow control since the flow works with the seat and not against it.

- Short stroke with fast response. The stroke length is typically ⅓ that of a globe valve, reducing the amount of droop (deviation from setpoint) in the regulator.

- A variety of seat coatings and seat materials to meet almost any application. The Jorcote seat is standard and delivers outstanding performance.

- The sliding gate design provides an area of closure, not just a line of closure. This area of closure reduces the effects of wire draw which is the most common cause of seat leakage.

- Less maintenance and downtime, and more opportunity to increase yields and profits.

- Easy maintenance. Your flow requirements change, and interchangeable Cv’s are available.

- The movement of the sliding gate seats generates a self-cleaning action.

Applications For Back Pressure Regulators

Our sliding gate back pressure regulators are ideal for steam, liquid, and gas media applications. Our team works with our customers to help achieve tangible results including lower operating costs, optimized performance, prolonged equipment life and higher productivity. You will see our back pressure regulators in a variety of applications including:

- For use in the food & beverage industry

- For high-pressure applications

- For fuel and oil burner control

- For fuel and oil atomization

- For natural gas applications

- For steam sterilization

Contact us for more information on how we can help you with your back pressure regulator applications.

Frequently Asked Questions

1. What’s the difference between a pressure regulator and a back pressure regulator?

Back pressure regulators perform the opposite function of pressure regulators. A back pressure regulator is normally closed while a pressure reducing valve is normally open. Secondly, the back pressure regulator controls upstream pressure, while a pressure reducing valve controls downstream pressure. Other than that, the valves operate identically.

2. How do you install a back pressure regulator?

A back pressure regulator controls upstream pressure and is installed at the end of the line (unlike a pressure regulator that controls outlet pressure and is installed at the beginning of the line).

3. How do you adjust a back pressure regulator?

To adjust a back pressure regulator you just need to adjust the screw at the top of the valve. You can tighten or loosen the screw.