Wafer Style Control Valves

The Mark 75 Series wafer-style control valves represent the next generation of control valves developed by Jordan Valve.

Built around the time-tested sliding gate design, these wafer control valves deliver numerous advantages, including reduced air consumption, easy installation, interchangeable Cv values, optimal flow control, and low maintenance requirements. Jordan Valve offers below four types of wafer type control valves.

Mark 75 Series ⟶

Wafer Style, Motor Operated, Very Precise

Mark 75HW Series ⟶

Wafer Style, Hand Operated, Precise Adjustment

Mark 75MV Series ⟶

Wafer Style, Motor Operated Control Valve; Sliding Gate; 1″ - 8″ (DN25 - DN200)

Mark 75PTP Series ⟶

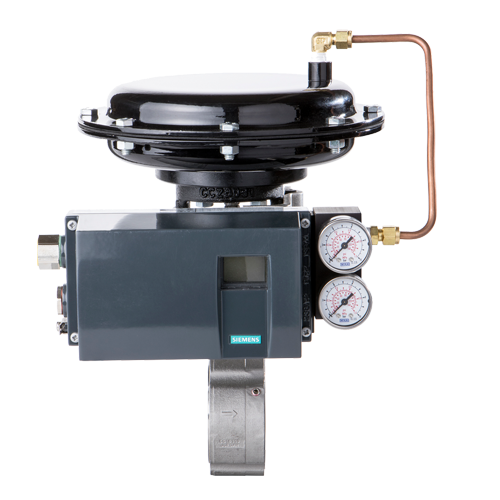

Piston Operated with Smart Positioner

Your List

Email List

Get A Quote

- The original Mark 75 Series control valve that is lightweight, compact body, exceptional performance and price.

- The motor-operated version along with a hand operated option.

- The handwheel operator allows the user to manually position the valve for optimum flow and lock in place.

- The piston operated version is used in on/off service.

Key Features

- Wafer Design – Reduces material usage, shipping costs, and installation expenses.

- Sliding Gate Seat – Short stroke design of these wafer type gate valves enables a smaller actuator and significantly lower air consumption.

- Light Weight – Much lighter than comparable globe or cage-style control valves.

Specifications

- Size Range: 1″ through 8″ (DN25 through DN200)

- Turndown Ratio: Up to 100:1

- Shutoff: ANSI Class IV tightness

Applications

The Jordan Valve Mark 75 Series Wafer Style Control Valves are widely used in the following applications:

- Steam

- Air

- Gas

- Oil

- Water

- Chemicals

Industries

These valves are commonly used across a wide range of industries, including:

- Food drink and brewing

- Specialty Gas Supplier

- Research Development and Technical Institutes

- Carbon Capture

- Hydrogen Economy

- Pharmaceutical

- Biotechnology

- Chemical

- Oil Gas and Petrochemical Industry