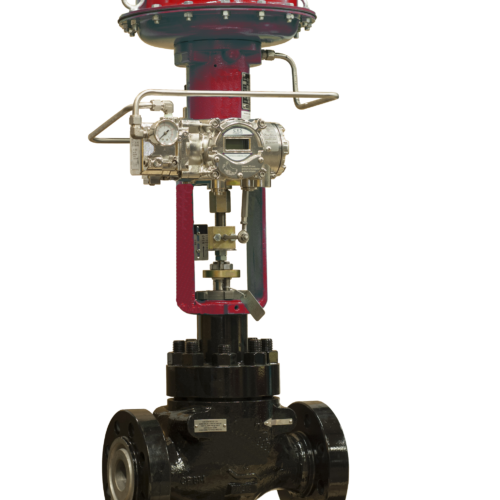

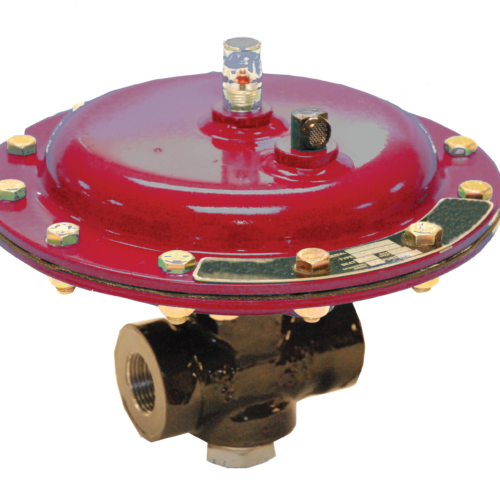

Globe Style/Cage Guided Control Valves

Jordan Valve offers a wide range of globe style/cage guided control valves that can be used in a variety of applications and services.

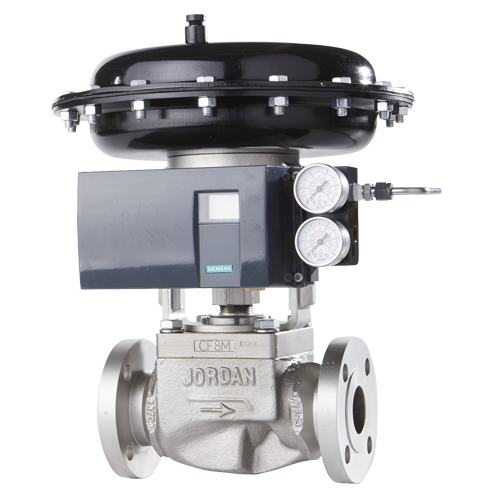

Mark 78 Series ⟶

Globe Style, Accurate Performance

Mark DBAQ Series ⟶

Angle Style Control Valve

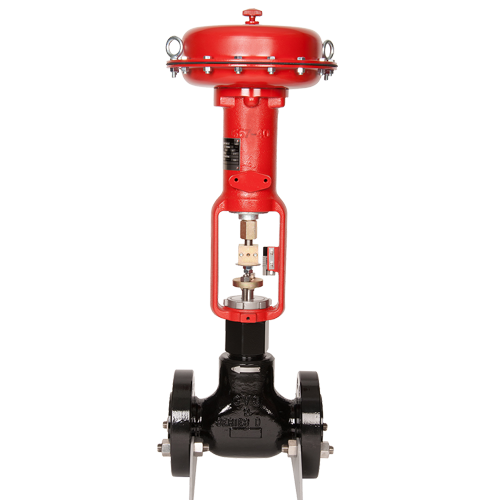

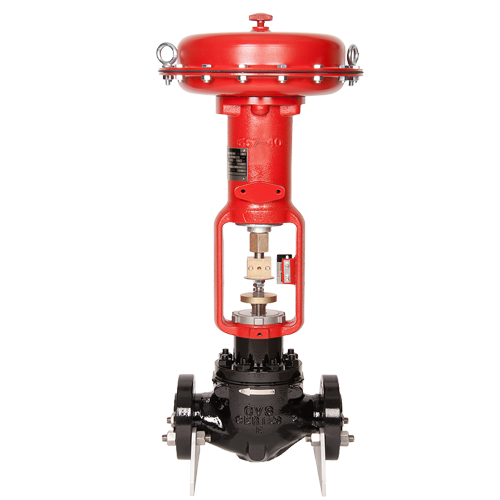

Mark D & DA Series ⟶

Globe & Angle Control Valve

Mark ED & ET Series (1″ – 6″) ⟶

Globe Style Control Valve

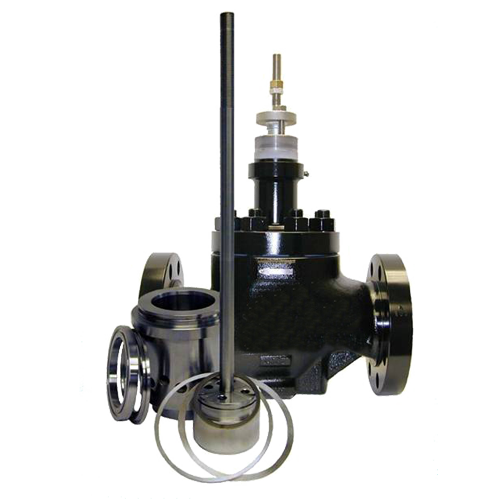

Mark ED & ET Series (8″) ⟶

Globe Style Control Valve

Mark EW Series ⟶

Globe Style Control Valves

Mark EZ Series ⟶

Globe Style Control Valve

Mark H-900, H-1500 & H-2500 Series ⟶

Globe Style Control Valves

Mark HPX and HPAX Series ⟶

Globe & Angle Style Control Valves

Mark 128PQC Series ⟶

Control Valve Suitable for On-Off Dump Valve Service

Your List

Email List

Get A Quote

Globe style or cage-guided globe valves are used across industries to improve stability and flow control in demanding and high-pressure applications. Jordan Valve’s cage-guided globe valves ensure consistent operation, even under high-pressure and temperature conditions. Our cage-guided globe valves feature a robust design and are engineered for durability. They are offered in various configurations to meet industrial requirements. These valves provide exceptional control, tight shutoff, and minimal maintenance, making them the ideal solution for critical fluid and gas flow regulation. Request a quote today!

Types of Globe Style/Cage-Guided Control Valves We Offer

Jordan Valve offers a comprehensive range of globe-style and cage-guided pressure and back-pressure regulating valves designed for precise control in industrial applications. This series includes various configurations to meet diverse process needs, including:

- Globe Pressure Regulating Valves – Featuring a straightforward yet effective design, these valves regulate downstream pressure with high accuracy, making them ideal for steam, gas, and liquid applications.

- Air-Loaded Globe Valves – These pressure regulators utilize an external air source for finer control over setpoints, providing enhanced responsiveness and adaptability in automated systems.

- Cage-Trim Pressure Regulators – Engineered for durability and precision, the valves use a cage-guided design to ensure stability and minimize wear, even in demanding conditions with fluctuating pressures.

- Piloted Back-Pressure Regulators – Designed to maintain a controlled upstream pressure, these valves use a pilot system for more accurate and consistent performance, making them suitable for applications requiring precise back-pressure control.

Jordan Valve’s Teflon and metal diaphragm options, quick-change seat rings, and unique sliding gate technology (available on select models) enhance performance, extend valve life, and reduce maintenance costs. These valves are commonly used in industries such as oil and gas, chemical processing, power generation and food and beverage.

How Does a Cage-Guided Globe Control Valve Work?

A cage-guided globe control valve features an internal movable plug or disc, which is attached to the valve stem and is guided by a surrounding cage structure. The cage is a fixed component that features precisely machined ports that guide the movement of the plug, ensuring its smooth and accurate movement in the valve body. It also controls the fluid flow by uncovering or covering the port areas in the cage when the plug is lifted or lowered. The guiding function of the cage enables this valve to act as a precise flow regulator, minimizing lateral forces on the stem. This valve design ensures superior stability and performance in many high-pressure drop applications.

Benefits of Using Globe Control Valves

Our globe control valves are designed for excellent pressure and fluid flow control across process industries. These valves are often chosen over competitor products due to the following reasons:

- The cage design of these valves helps center the valve plug, assuring better shut-off capabilities and minimizing the risk of potential leaks. These factors contribute to accurate flow control.

- The cage guides the plug, reducing wear and tear on the sealing surfaces and thereby extending the lifespan of the valve.

- The cage design of these valves helps mitigate cavitation by preventing the vapor bubble collapse and ensures quieter operation.

- These valves enhance operational efficiency as they are less prone to vibrations due to the stable guiding mechanism.

- They can be used for various applications involving corrosive or viscous liquids, process gases, or utility steam.

Applications of Globe Control Valves

We provide globe control valves for steam, liquid, and gas media applications that require flow regulation, tight shutoff and throttling capabilities. They are used to:

- Regulate the flow of water into the boilers

- Control the flow of chemicals and other substances during production

- Control the water flow through pumps, filter, and other equipment

- Regulate the flow of hot geothermal brine between heat exchangers, wells and reinjection lines

- Isolate and regulate the flow of carbon dioxide captured within carbon capture and storage (CCS) systems

We can customize the cage-guided control valves for use across:

- Boiler vents and drains

- Cooling water systems

- Fuel oil systems

- Feedwater and chemical feed systems

- Turbine seals and drains

- Turbine lube oil system

Frequently Asked Questions

- Can I use cage-controlled globe valves in varying flow control applications?

Yes, cage-controlled globe valves ensure stable control in fluctuating flow conditions. Their cage design helps to maintain consistnt flow and pressure regulation, ensuring reliable performance even in challenging conditions.

- Do you offer customized cage-controlled globe valves customizable?

Yes, we provide customization options for all our cage-controlled globe valves, including different materials, sizes, and end connections. This allows you to tailor the valve to meet the specific requirements of your application. - How do I size the right cage-controlled globe valve for my application?

To ensure proper valve selection, use our Jordan Valve’s sizing software or consult a local representative. The software will help you size the valve based on flow rates, pressures, temperatures, and other system conditions.

- How should I choose the right cage-controlled globe valve for my application?

Choosing the right cage-controlled globe valve for your application requires consideration of several key factors, including:- Flow rate

- Temperature and pressure

- Fluid characteristics

- Valve size

- Trim selection

- Body, trim, and seal materials

- Flow control requirements

- Flow patterns

- Durability and maintenance needs

- Actuation and automation requirements

- Future expansion